Day #8: Really Consistent Shooter Prototype

Prototyping

Intake Prototype

The intake was totally redesigned in Solidworks today. The design features multiple sets of belts to move the frisbees around. It uses belts on the bottom to increase the friction between the disc and the polycarbonate sheet. In total, 11 belts need to be manufactured and welded. The newly designed intake prototype is currently under development.

The conveyor prototype

Welding the polyurathane belts for the new intake

Making modifications to the intake roller

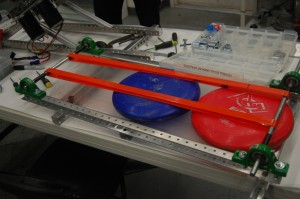

Shooter Prototype

Students made changes and modifications to the shooter prototype. C-channels were added on the left and right side of the prototype to guide the frisbee as it travels through the shooter's wheels, preventing it from moving upwards and adding stability. In addition, new parts and attachments for the shooter were milled and manufactured.

The shooter prototype

The shooting prototype was tested extensively. As the results show, the frisbees that were fired were somewhat accurate. The orientation of the frisbee (upside-down vs. right-side-up) appears to have a slight influence on the trajectory of the frisbee. An upside-down frisbee ends up at a smaller height than the height of a right-side-up frisbee.

2010 Robot

Makeshift bumpers were added to the 2010 robot today. The bumpers were constructed out of pool noodles, which the students will use to create the real bumpers from later on. The team hopes to use the 2010 robot's drivebase to attach and test the intake and shooter prototypes upon their completion. Metal frames were also installed on the robot. With these bumpers, students can test the intake mechanism as if it were on the real robot.

The 2010 robot with bumpers and metal attachments

Programming

The programmers worked on a multitude of tasks today. Some students worked on a custom Smart Dashboard widget that would populate a text file with a constant's name and value, then upload the file to the robot with FTP. Currently, the widget is working, but students still have to investigate problems with the FTP connection.

Students also worked on automous command scripting. With this, the robot can read autonomous commands from a text file on the robot, and execute them. The benefit of this method is that the team won't have to re-compile or re-deploy the code in order to make one small modification to the autonomous. Currently, the system is working as intended. The robot was able to interpret the drive and wait commands.

Lastly, the programmers continued to work on reading constants from a file. This has not yet been completed, but the students have a general idea and framework for what needs to be written.

Programmers programming

Pat Fairbank

This is a prime example of our foremost Canadian mentor in his natural state of observation and intense thought about the world of robots.

Pat being Pat

Action Items

-

Finish intake prototype

-

Mount said prototype to 2010 robot(onslaught)

-

connect all 3 prototypes and test from start to finish(Intake-Conveyor-Shooter)

-

Programming-work on reading constants from a file

Lab closing time was 12:50 A.M.