Day 53: Rain Won’t Stop Our Excitement and Preparation for Madera

Co-Authored by Tyler Cuff and Robert Lim

Testing

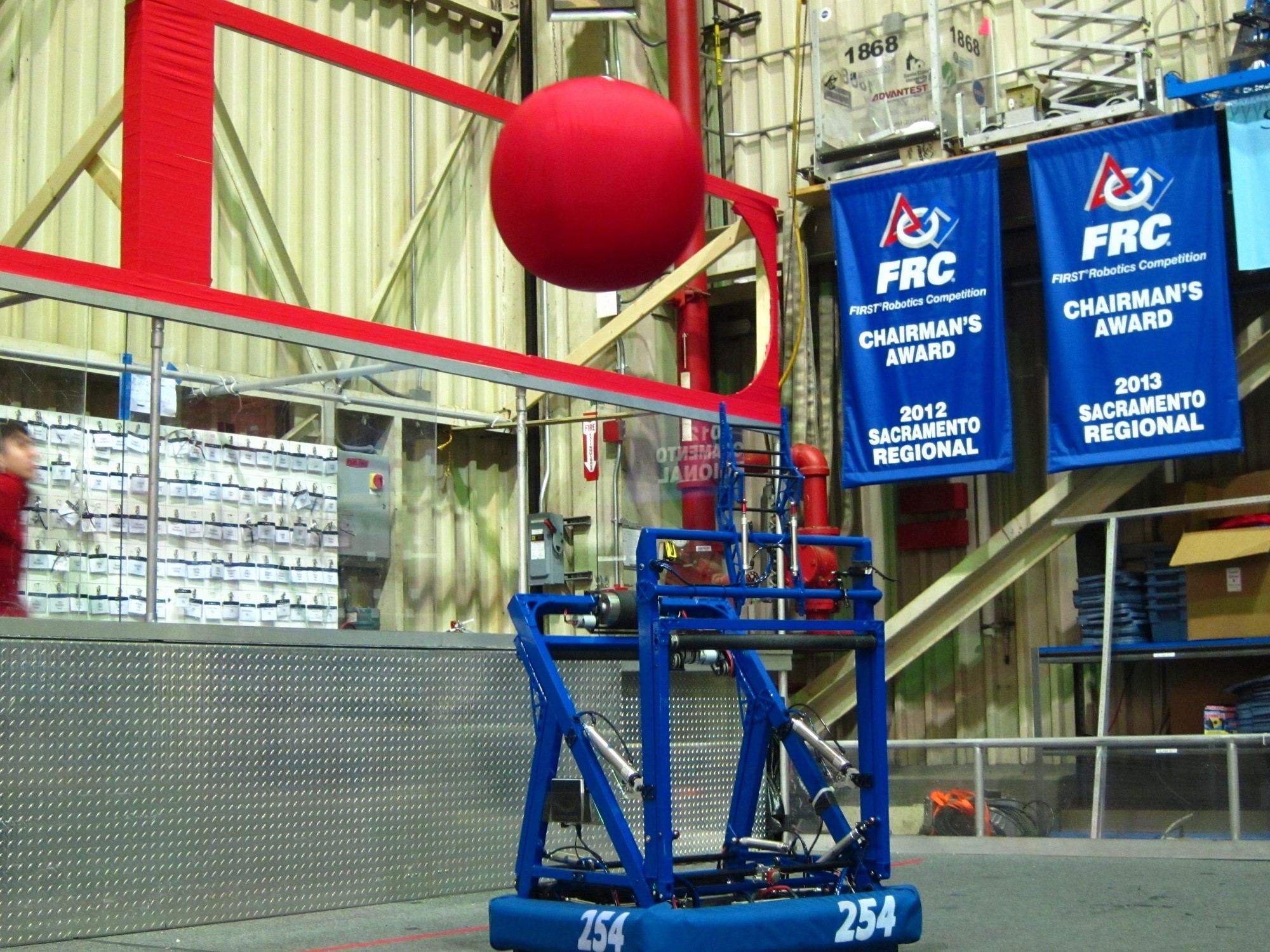

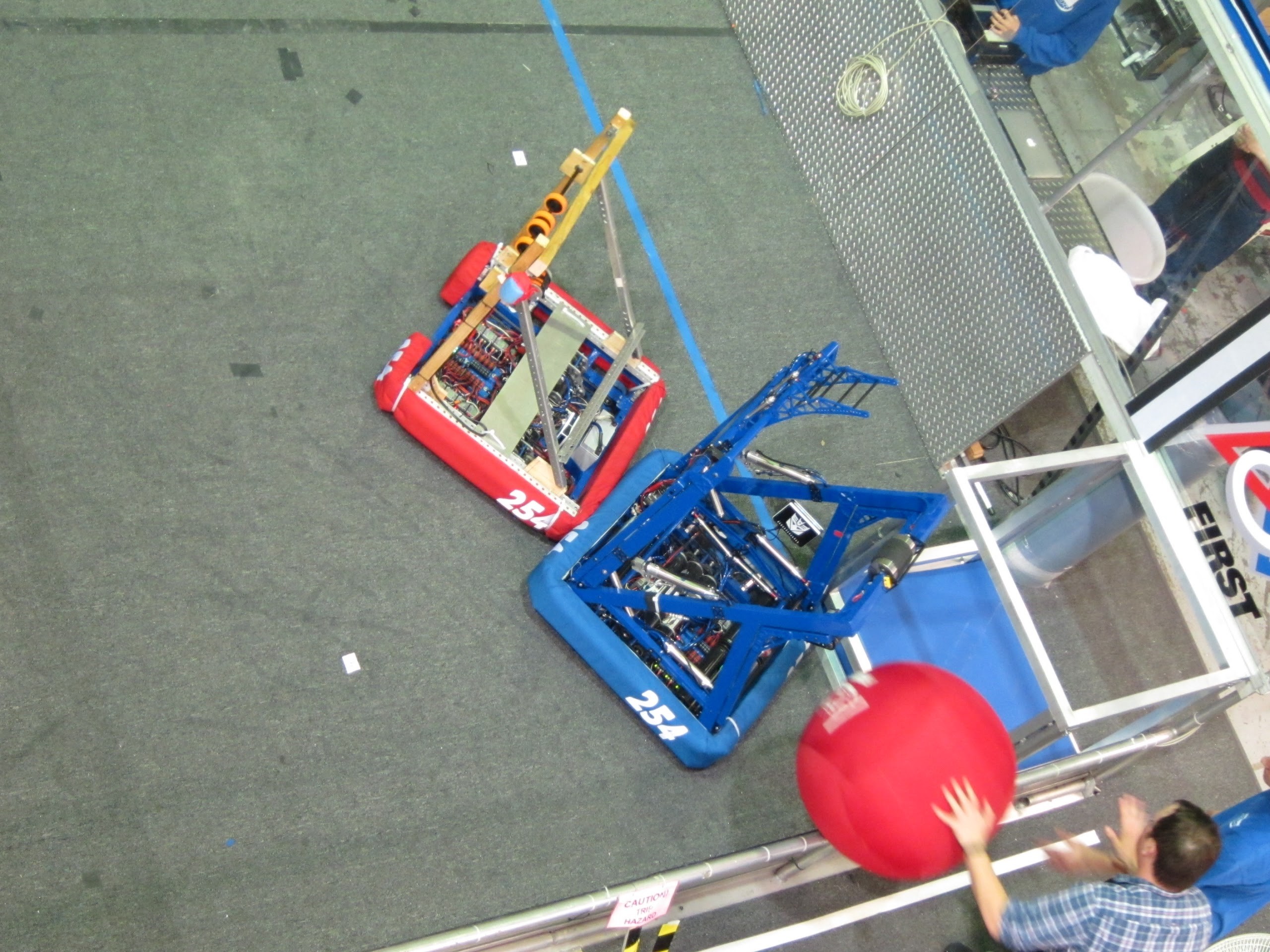

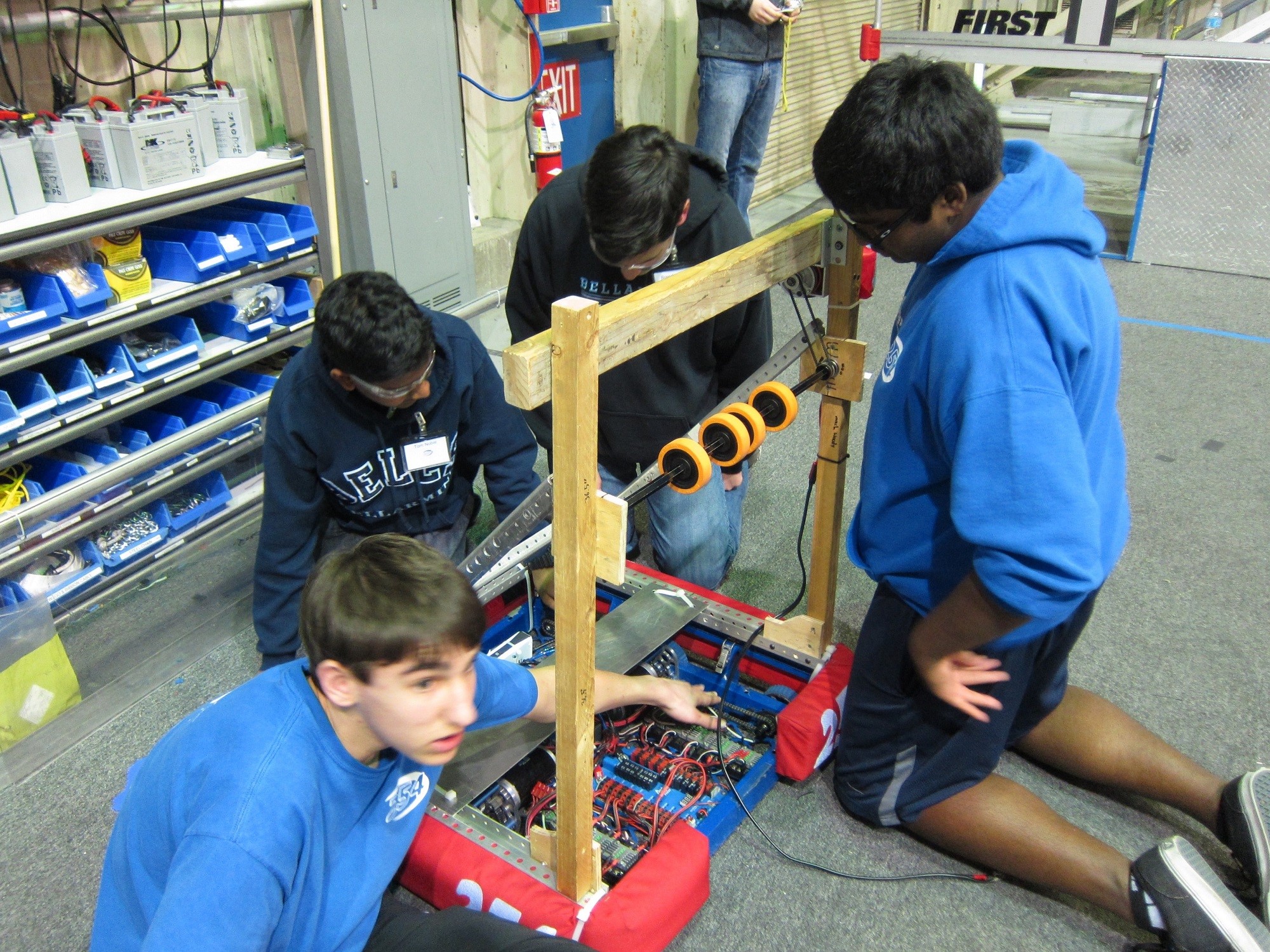

The day began with students and the drive team practicing and troubleshooting the robot. The drive team traversed the field and practicing scoring goals as quickly as possible.

After Skystalker, the surrogate opponent robot, was up and running, the driver practiced scoring with its uncooperative counterpart playing defense (see image below) This accustomed the driver to moving around the field with an opposing robot attempting to block movement and impede shooting.

Electronics and Wiring

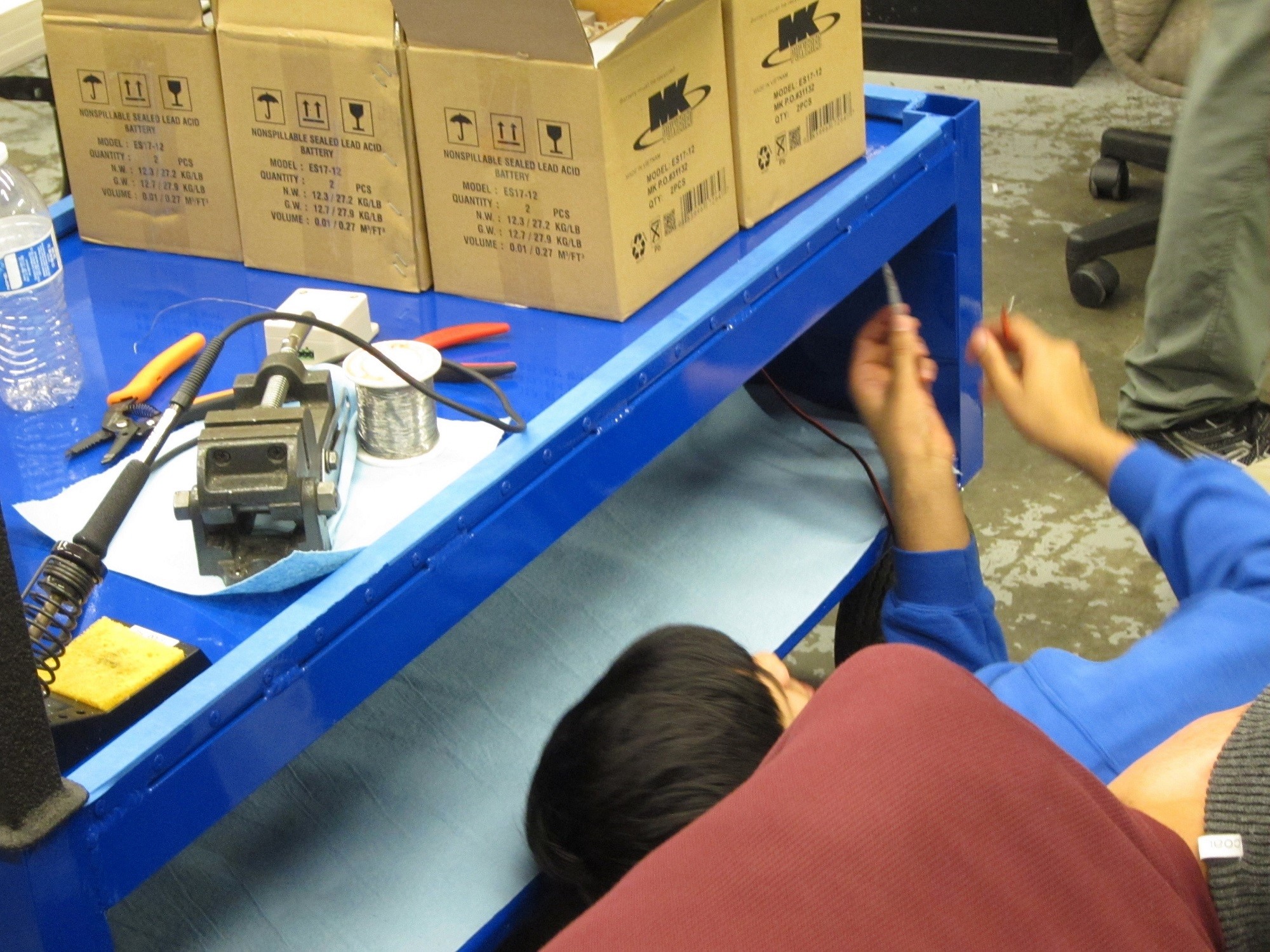

During a half hour window of robot downtime, students attended to other projects. Students installed lighting in the battery cart and added a vinyl finish. Meanwhile several other students worked on improving the wiring of Skystalker by loosening its chain for the drive train.

Parts Organization

The main piece of organization was the continued efforts on the Bill of Materials, pronounced Bom in airports, needed for Madera. The BOM will describe a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product).

CAD

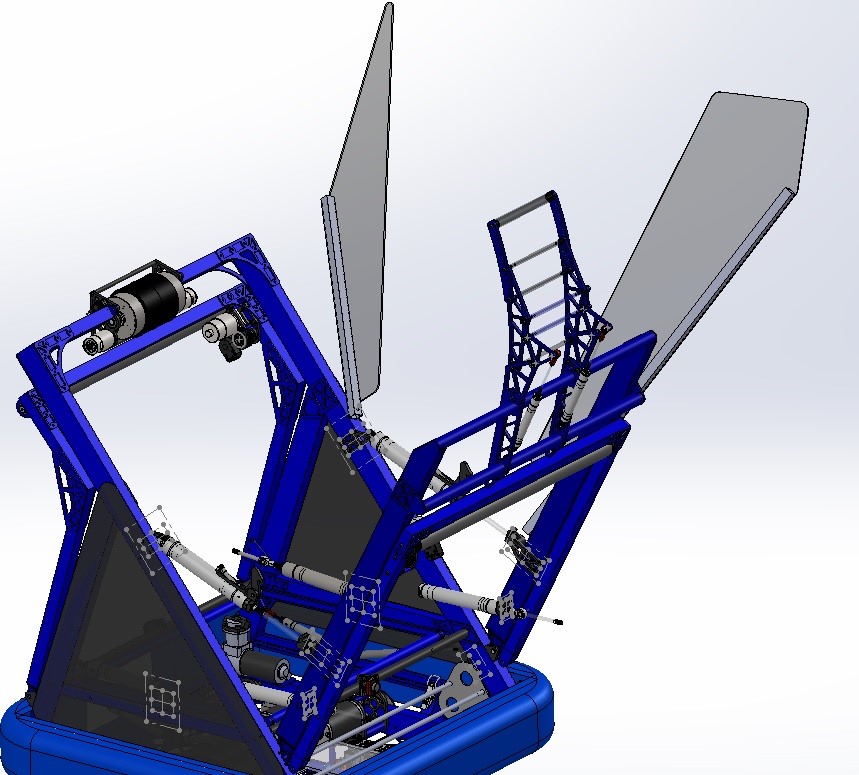

Several student worked on completing the SolidWorks CAD tutorial to improve their practical knowledge of CAD. The majority of them created sketches while others put together assemblies.

Awards

A team worked on the Chairman’s Award presentation PowerPoint for the upcoming Madera tournament in March. A leader began to finalize the script. Remember that our Chairman’s presentation is confidential and should NOT be shared or discussed outside of the team. Another team worked on the Media and Technology Innovation Award that is due tomorrow. Its content was finalized with approval throughout the team and the graphic design and layout format will be finished tonight.

Design

Upstairs, students had a discussion on how to improve the robot and what will definitely will happen. We will be adding the side panels for giving proper recognition to all our amazing sponsors. Two suggestions were adding triangular plates onto the side of the robot to assist in catching, and another involved the addition of surgical tubing to strengthen the catcher.

Miscellaneous

The lab received a new printer, scanner/copier, and 24″ monitors. With the recent rain, a few students noticed a small leak in roof on the east side of the lab. The team also played some pick-up volleyball with an exercise ball and the truss.

Action Items

- Driver practice

- Build control board

- Machine, anodized, and then remachined

- Print handles

- Make control board standoffs

- Prototype catcher

- New accumulator standoffs

- Drill Grommet holes on spare intake

- Set up us up the BOM

- Film fly through scene

- Technical Binder

- Wire Batteries

- Test Batteries

- new pinniped standoffs

- cut, weld, and powder

- Mentor Castle prep

- Autonomous vision targets and lights

- Make wheels

- Redesign catcher pistons