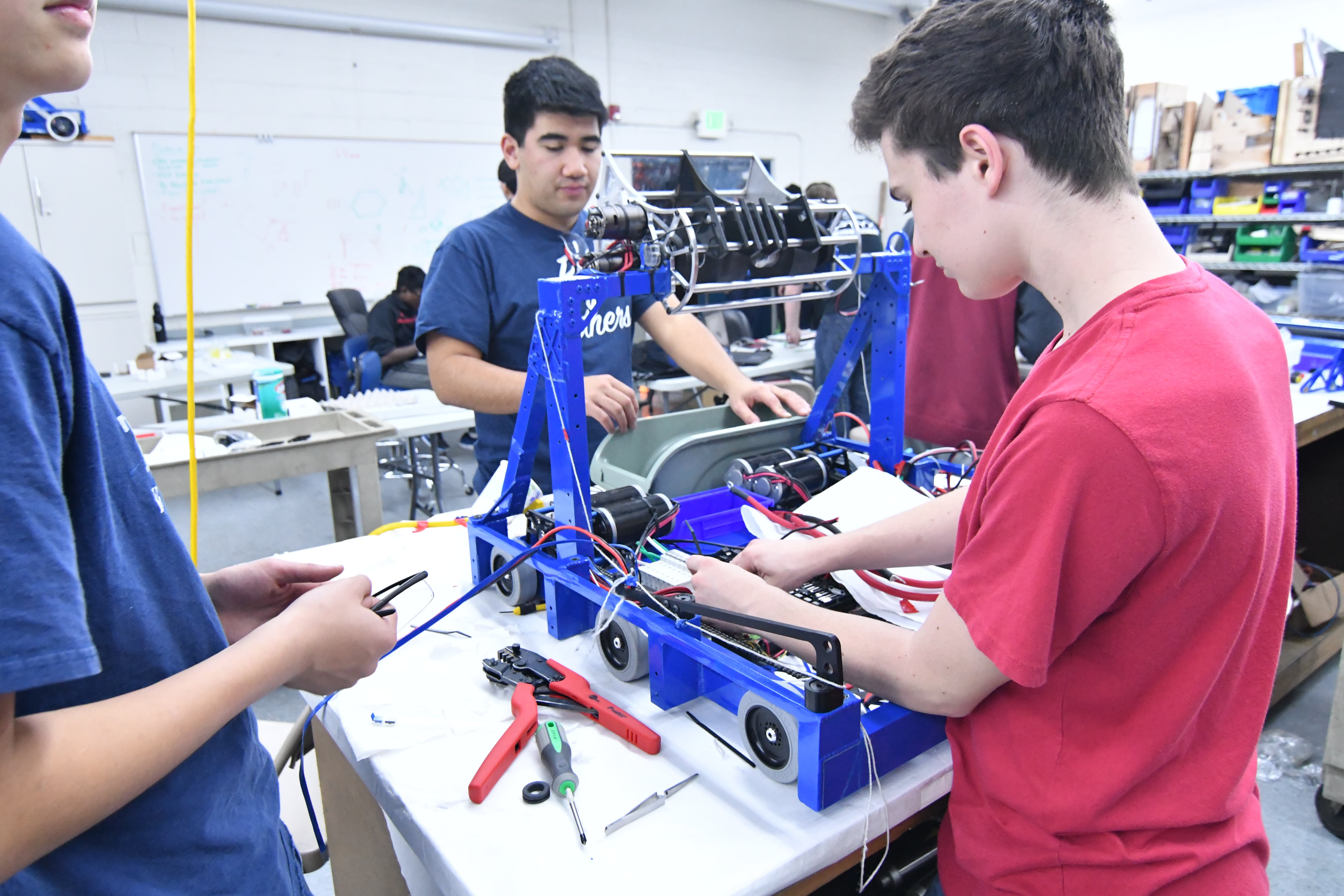

2017 FRC Build Season Blog

2017 Winners of Chezy Champs!

A Brief Summary

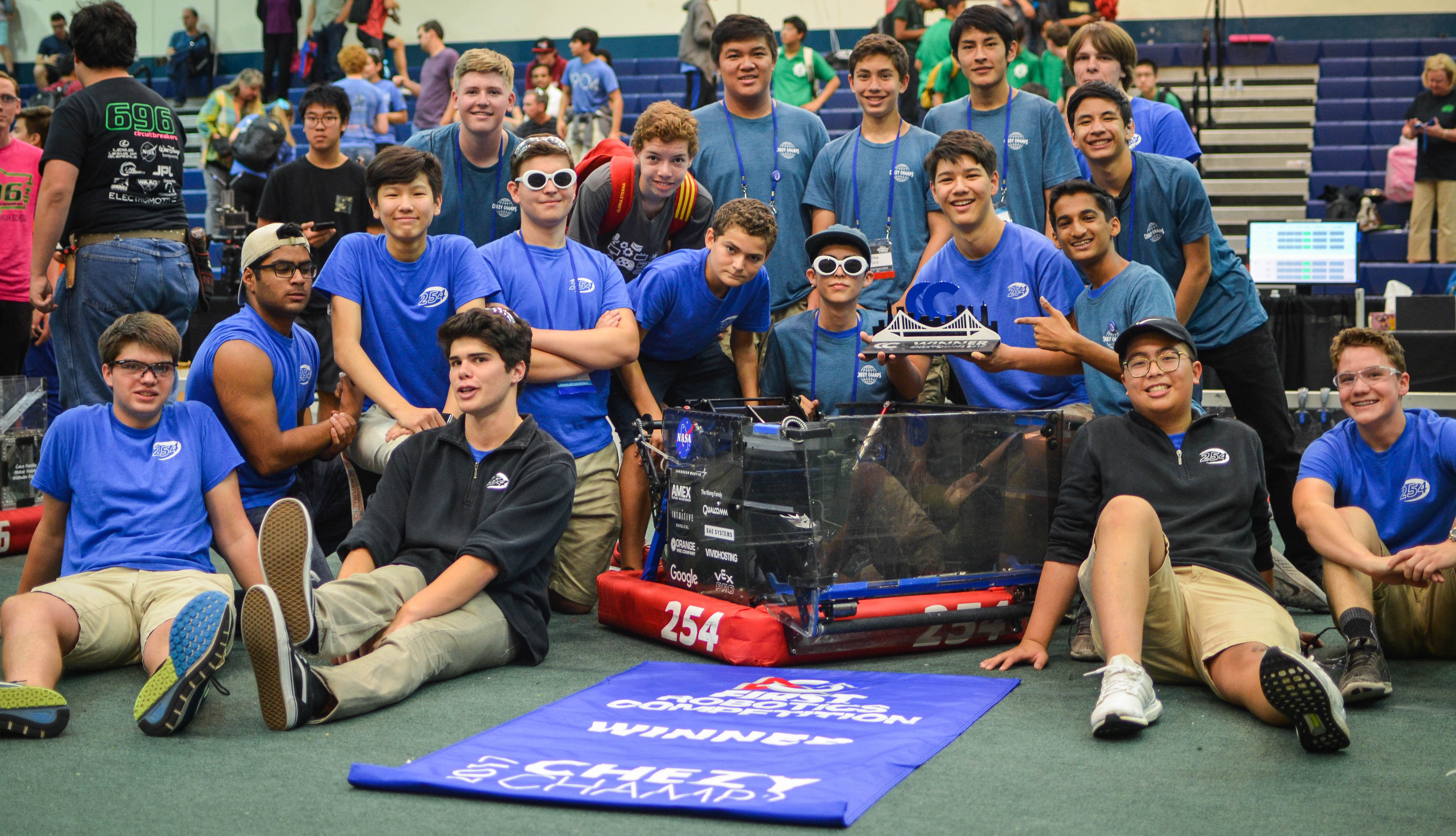

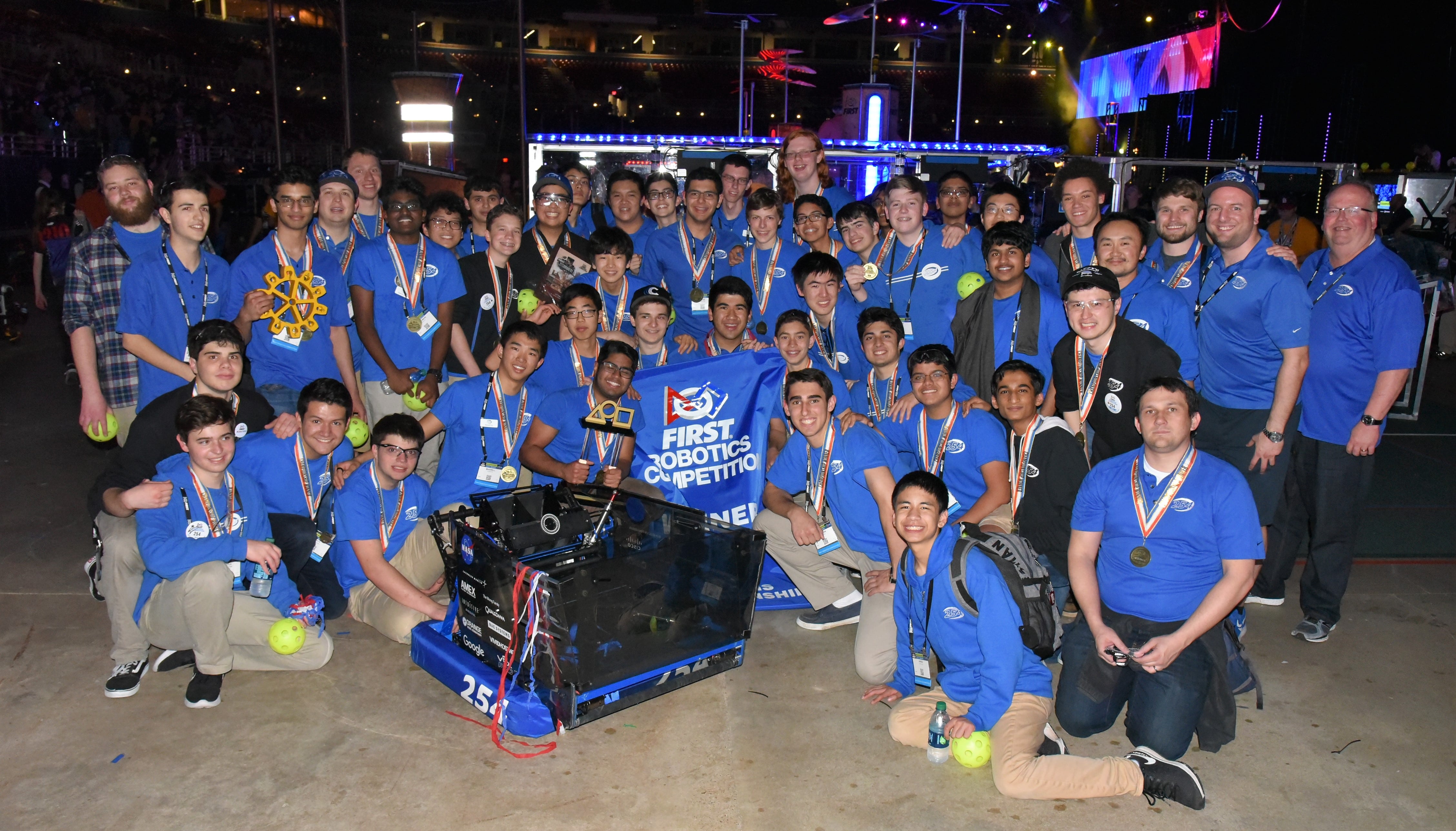

As part of an eventful weekend, we hosted Chezy Champs, our annually hosted offseason FRC tournament at Bellarmine College Preparatory, in our hometown of San Jose, CA. We had a great time jumping back into action with our robot, Misfire, before the start of the 2018 FRC Season. Alongside, FRC Team 1011 Team CRUSH, FRC Team 696, Circuit Breakers, and FRC Team 5104 BreakerBots, we were able to win the tournament!

Team 254 Members pose for a picture with Misfire after winning at Chezy Champs 2017

Event Highlights

General Highlights

Check out this great highlight reel made by RoboSports Network (RSN)!

Exhibition Match

At the tournament, we hosted an exhilarating exhibition match, which included the several teams with highly skilled shooting robots. The standard rule for this match was that the only way to score points was to shoot fuel into each alliance’s respective boiler. The teams which participated in the exhibition match:

The Blue Alliance

- Team 971 Spartan Robotics

- Team 973 Greybots

- Team 1678 Citrus Circuits

The Red Alliance

- Team 254 The Cheesy Poofs

- Team 1323 Madtown Robotics

- Team 3309 Friarbots

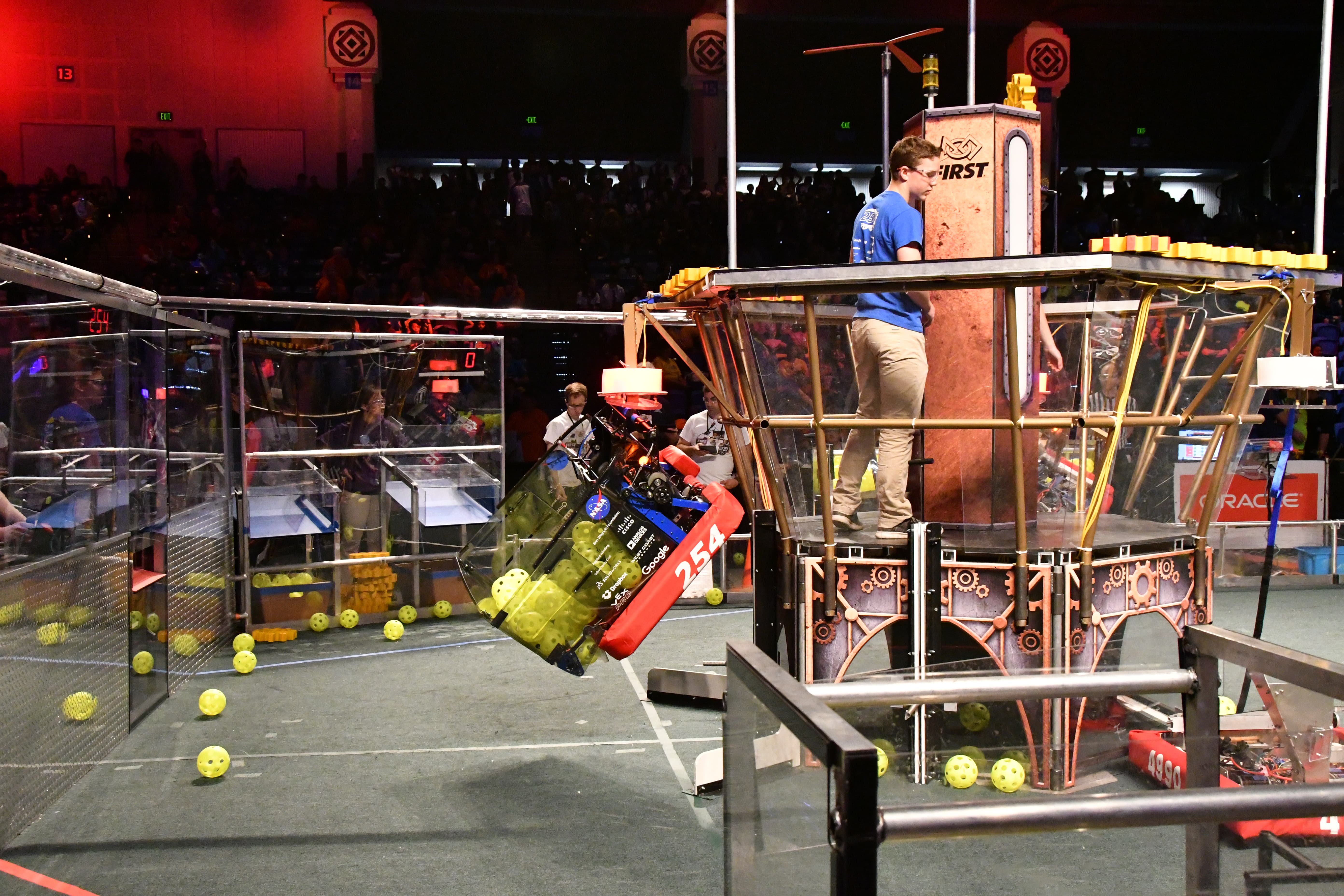

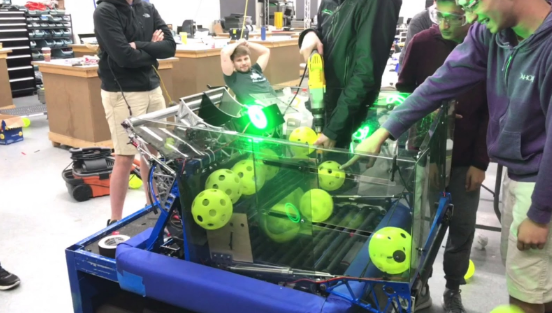

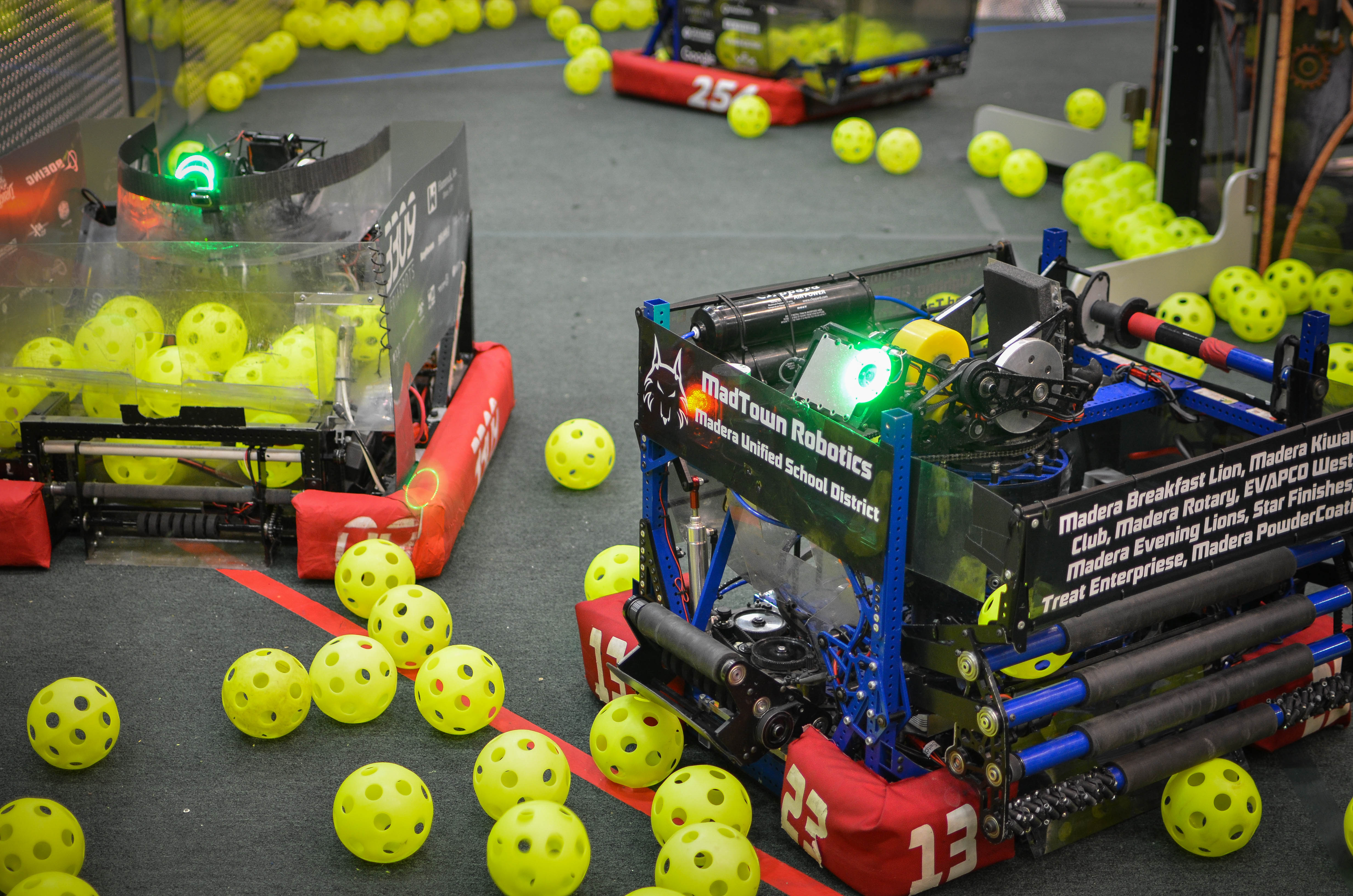

Team 1323, Team 3309, and Team 254 work together to gather fuel to shoot into the boiler

The Red Alliance started off with a significant lead by scoring 50 fuel balls into the boiler, making it an amazing show for the audience to see 3 robots scoring fuel into one boiler at once! Eventually, the Blue Alliance slowly started catching up with the Red Alliance by consistently scoring their collected fuel into their boiler. With a minute left in the match, the our friends from Team 973 displayed their true defensive skill by blocking Team 1323’s path across the field. Though the Blue Alliance’s efforts were equal to that of the Red Alliance, the Blue Alliance was unable to keep up with the pace of the Red Alliance. After the great efforts shown by both alliances, the Red Alliance came out to be the winner scoring 203 kPa compared to the 97 kPa scored by the Blue alliance. The Exhibition Match Video can be viewed here.

A Special Thanks

Chezy Champs was very special this year due to the efforts of so many people and organizations. Team 254 would like to thank our friends from RoboSports Network (RSN) for providing our audience with such a great analysis of each match and team at the tournament. We would also like to thank all the volunteers, who helped make Chezy Champs possible. It was truly an incredible experience to host an offseason tournament attended by so many talented teams, even those who chose to attend from out of state, and to make new friends and catch up with old ones too!

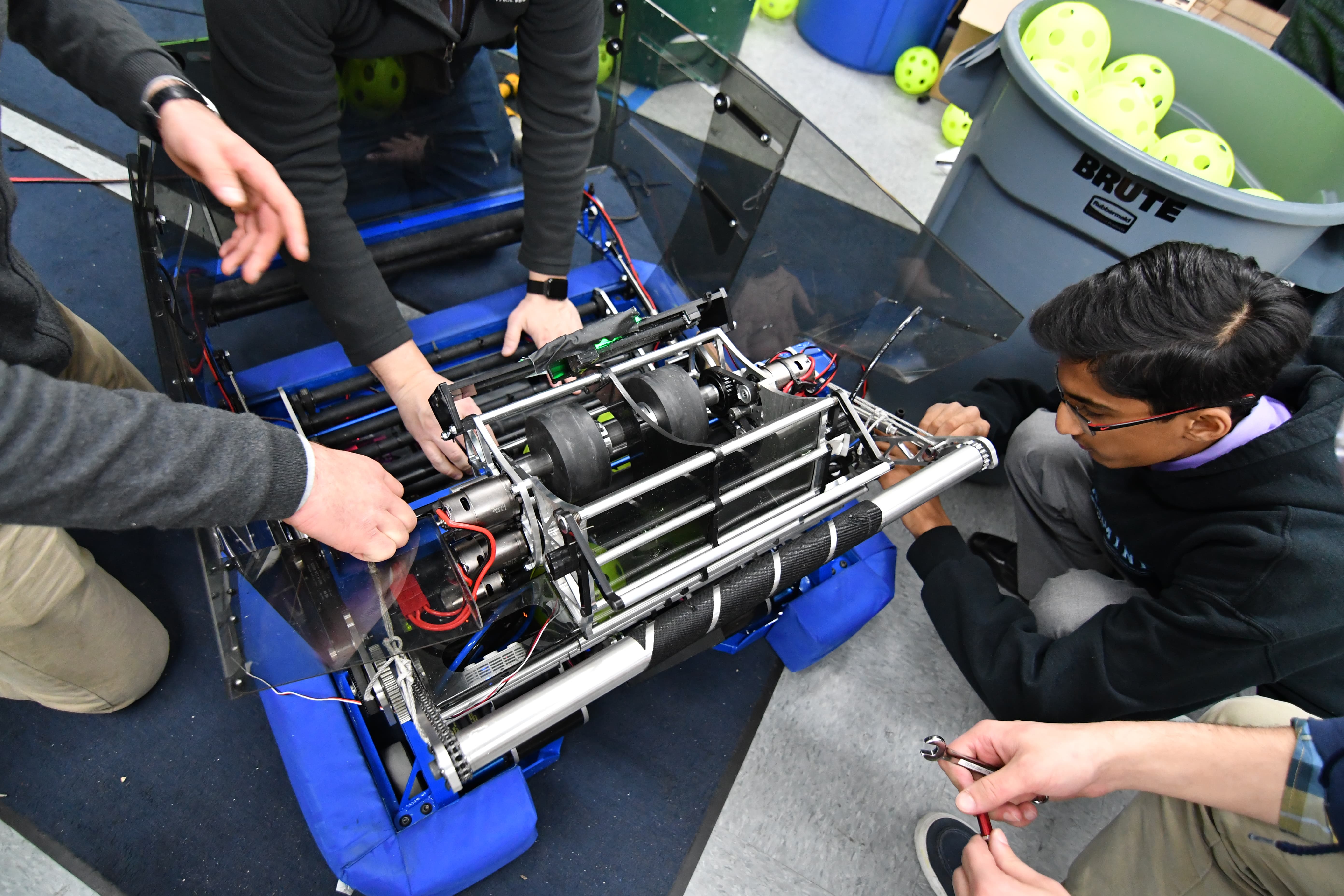

Robot Performance

Throughout the qualification matches, we encountered a few mechanical problems with our gear grabber, hopper, and drivetrain and a few problems with Misfire’s autonomous performance. After some careful observation, we realized that our gear grabber’s knife-edge was worn out, so we replaced it with a new piece of polycarb. Our stationary hopper panel kept colliding with the field hoppers, which tore our hopper wall. We replaced the broken hopper panel to solve this problem. We also noticed a crimp lodged between our chain and sprocket on our drivetrain, so we removed it to make our drivetrain function normally. Overtime, our autonomous performance improved after our mechanical changes. Thus, we were able to seed first for alliance selection after having a qualification match record of 7 wins and 3 losses.

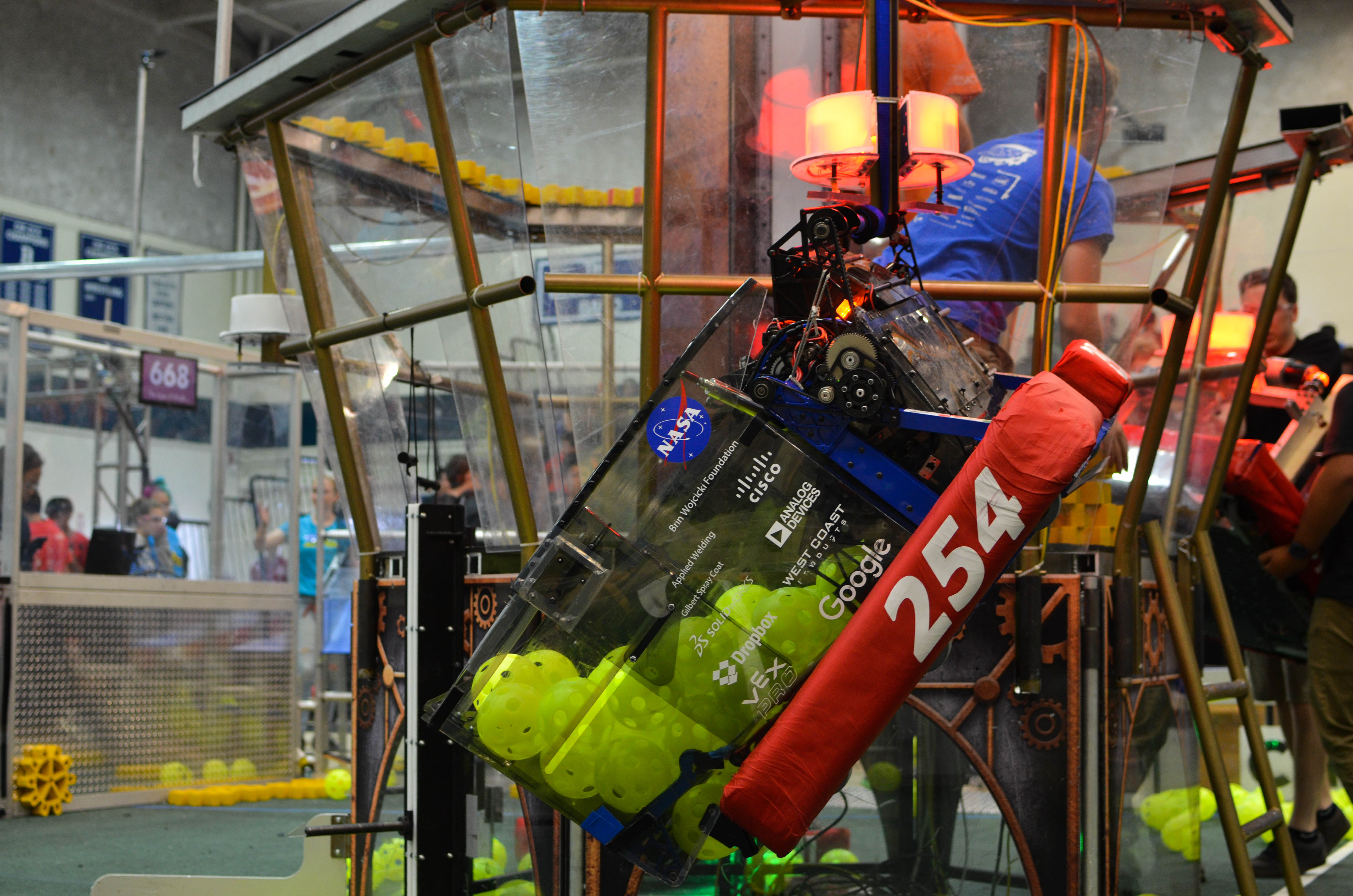

Misfire successfully hangs within the last few seconds of a Qualification Match

During elims, we faced some fierce competition during our Semifinal and Final Matches. We ended up having to compete in a third tiebreaker match in semifinals and finals. In Semifinals Match 2, the opposing alliance of Team 973 Greybots, Team 1538 The Holy Cows, Team 604 Quixilver, and Team 2135 Presentation Invasion, scored a large amount of kPa during auton and kept their lead up by activating all 4 rotors! In Finals Match 2, the opposing alliance of Team 1323 Madtown Robotics, Team 3309 Friarbots, Team 5026 Iron Panthers, and Team 2073 EagleForce, displayed their true skill, by keeping a consistent lead, from the start of the match. By the end of our elimination matches, we won all of our tie breaking matches, allowing us to win the event with our alliance. We wouldn’t have been able to accomplish such a victory if it weren’t for our amazing alliance partners – Team 1011 CRUSH, Team 696 Circuit Breakers, and Team 5104 BreakerBots.

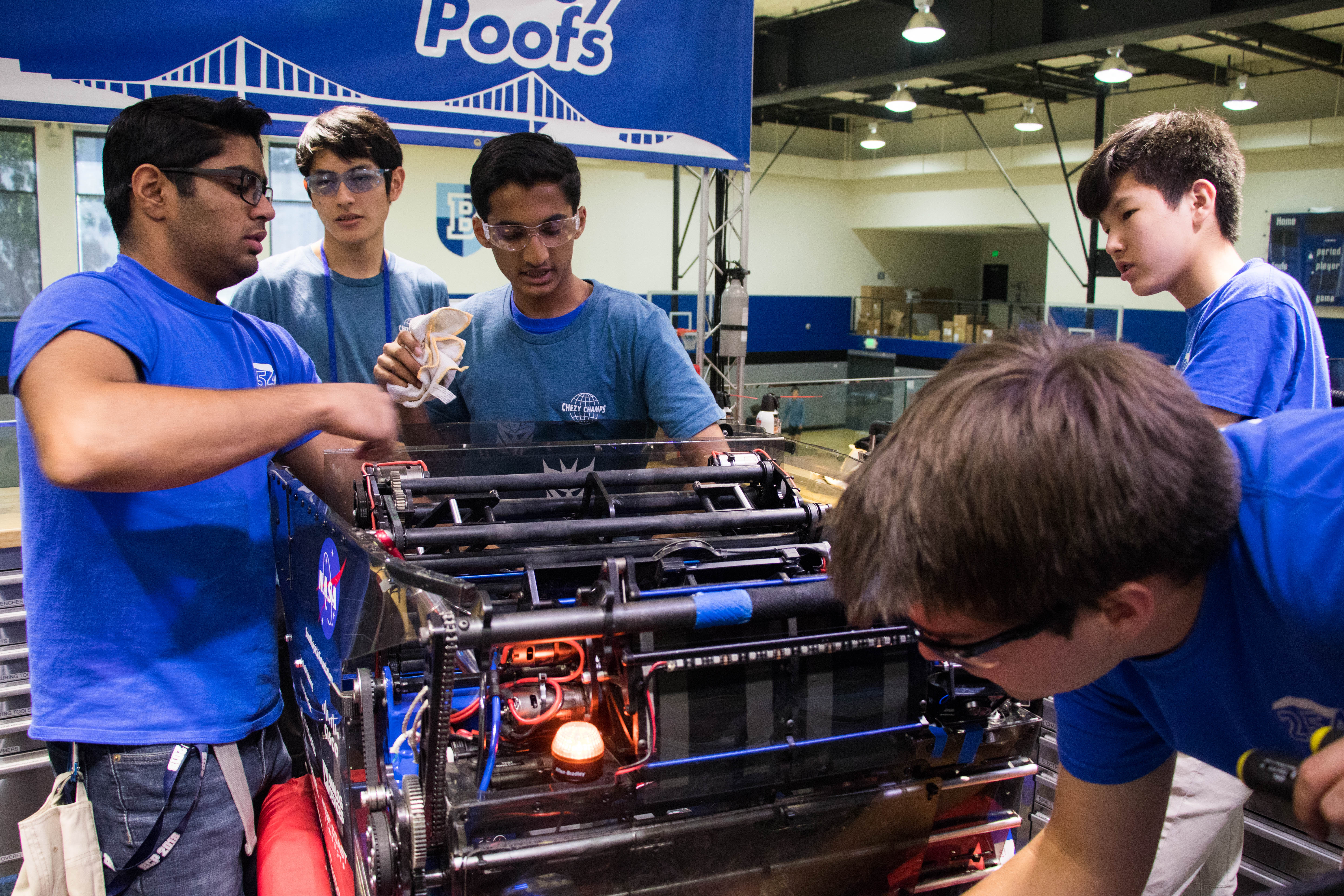

Members of the Team 254 Pit Crew repair Misfire before an upcoming Finals Match

2017 Technical Resources Release

Team 254 is proud to present the Technical Binder, Code Release, and Blog Release for our 2017 World Champion winning robot, Misfire. If you have any questions, feel free to comment on the Chief Delphi thread for our code release and our technical binder release.

Festival of Champions

2017 FRC Class of FIRST Champions

Recently, we attended the first ever FIRST Festival of Champions in Manchester, NH. After winning the St. Louis Championship with our extraordinary alliance partners, we faced the Houston Championship winning alliance in an intense series of 5 matches. Alongside Team 2767 Stryke Force, Team 862 Lightning Robotics, and Team 1676 The Pascack PI-oneers, we were able to win the Festival of Champions Event. We enjoyed a tour of DEKA and a great potluck at Dean Kamen’s home. We would like to say thank you to FIRST for giving us the amazing opportunity to participate in this event!

“Thanks to the phenomenal performance by our alliance partners!”

Championship Matches

In the most intense games we’ve played all season, the Houston alliance won the first two matches. Our alliance won the third and fourth to stay in the game. In Match 4, our alliance partners helped us win against the Houston alliance by a margin of only 16 points. In the final match, our alliance capped a great season with one last win. We won the match, and the festival championship, setting a record high score for this year’s game of 588. We’ll let the video speak for itself, as our last finals match was certainly one of Team 254’s best performance of the season.

We would like to honor our alliance partners because of how far we all came, from St. Louis to Festival of Champions. We would also like to thank Team 973 Greybots, Team 5499 The Bay Orangutans, Team 1011 CRUSH, and Team 2928 Viking Robotics from the Houston Alliance for setting the bar high and making all our matches an intense, and great experience. We’re excited to meet other FRC teams at our annual offseason event, Chezy Champs, and to kick off next year’s season!

2017 World Champions!

This past week, we attended the FIRST Robotics Competition Championship in St. Louis. With two Championship events this year, it was hard to decide which to compete at, but we had a great time facing off against teams from the east coast, Canada, and more. Alongside, Team 2767 Stryke Force, Team 862 Lightning Robotics, and Team 1676 The Pascack PI-oneers, we were able to win the Daly Subdivision finals before continuing on to win the Championship at Einstein.

Daly

In our qualification matches, we went 7-3 overall and seeded second, with Team 2767 holding first seed. The improvements we made since the Silicon Valley Regional payed off as we hit over 100 kPa during our second qualification game and managed an average of about 381 points per match. Throughout qualifications, we were also regularly able to achieve 40 kPa and activate 4 rotors, giving us enough ranking points to propel us into a high seed.

Moving into alliance selection, we joined Team 2767 alongside Team 862 and Team 1676. With a balance of gear and fuel scoring ability, we planned to maximize our points by hopefully achieving 40+ kPa and activating 4 rotors every match. Throughout the Daly finals, we remained undefeated and won against incredibly fierce competition. In our first semifinals match, we managed to score a personal record of 550 points! We were also very grateful to have received the Innovation in Control Award, an award we had also received back at the San Francisco Regional. After winning Daly with some very close matches, we were anxious to see how we would perform at Einstein.

Einstein

In a round robin style tournament, we competed against every other subdivision champion throughout 5 matches. We ended up going 3-2 here and seeded second, giving us the opportunity to compete in the grand finals as the blue alliance against the Darwin champions, who had beaten us in the round robin tournament.

In the most intense games we’ve played all season, our alliance pulled ahead in the finals, winning the second match by only 3 points. We’ll let the video speak for itself, as the second finals match was certainly many on 254’s favorite game of the season:

We are so grateful to our alliance partners for playing such a huge role in our success, and to every team that attended the Championship for competing with us and making it such an amazing experience. Special mention to the Einstein teams for going all the way and challenging us in ways we hadn’t previously been. We’re looking forward to facing off against the Houston alliance at the Festival of Champions!

“Thanks to our mentors for such a great season!”

“Post-Einstein excitement”

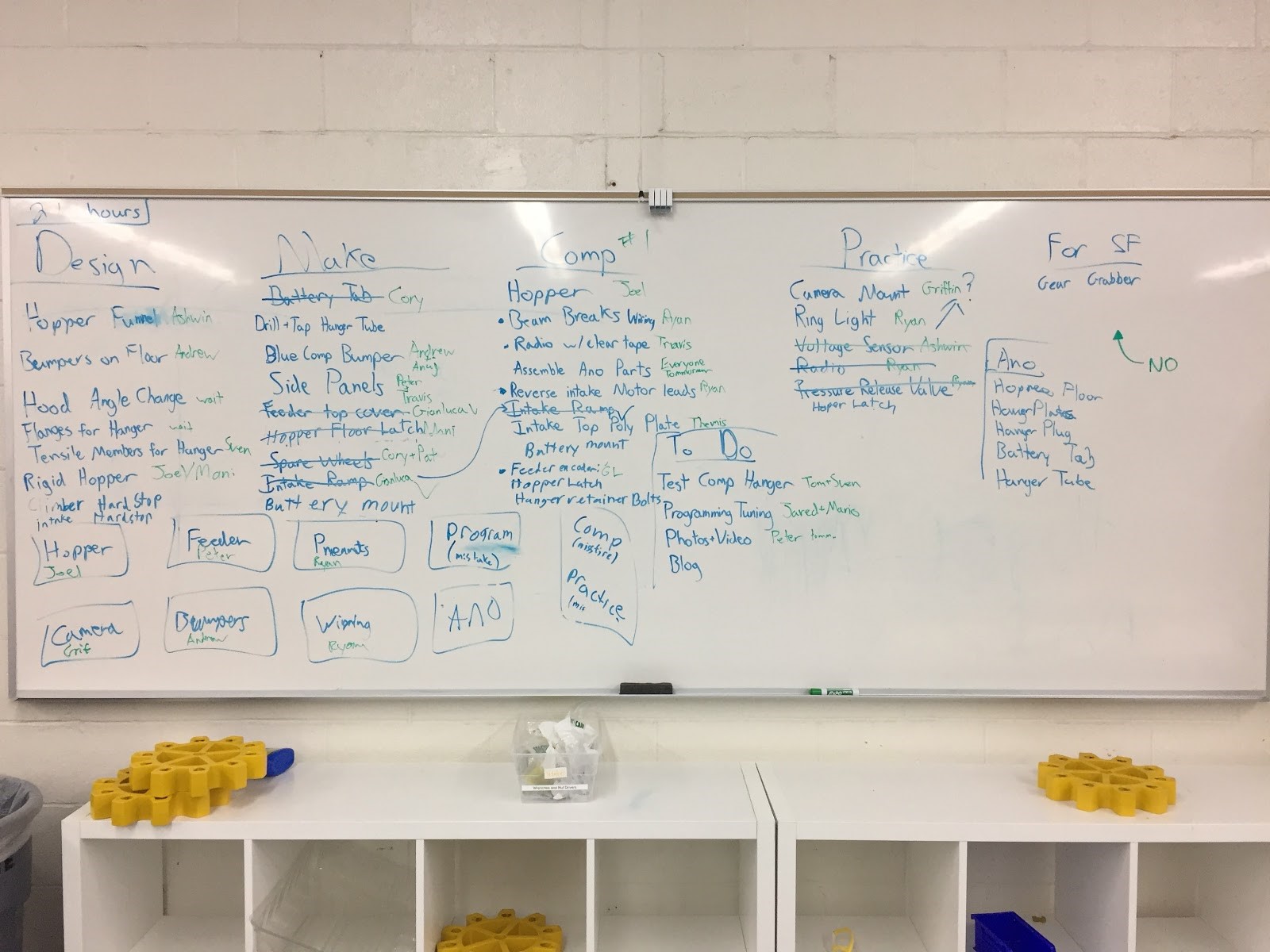

FRC Day 42 Build Blog

Day 42: Preparing for World Championships

Quick Summary

Everything that we need at competition, which includes the pit, was packed and prepared for being shipped to St. Louis.

Robot Progress

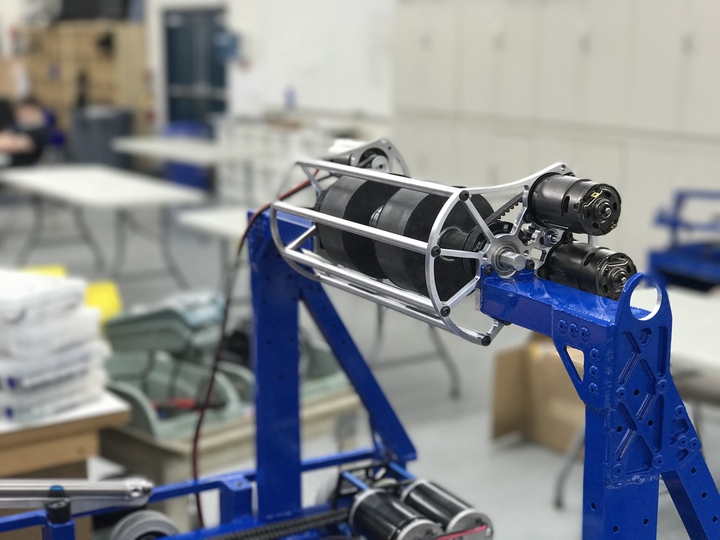

Shooter

We worked on some hood geometry and started to look at the placement of the hanger tube and different sizes. We also finished the design of the new hood and CNCed the new hood plates. We laser-cut a new center divider for the hood. Everything was assembled at on Monday’s build.

Hopper/Intake Ramp

The old hopper broke on the practice bot, so we laser cut new plates and assembled them onto the robot. We also cut spare hopper plates and spare intake ramps in case we need them during champs.

Driver Practice

We started practicing a new kind of gear cycle called the check mark cycle, which we plan will probably use from here on out.

Programming

Today, we worked on shooter tuning and semi-automated gear placement in teleop using an ultrasonic sensor. For shooter tuning, we worked on fixing a problem where our stream will begin to walk backwards over long periods of time. We believe this is a result of the system becoming more efficient over time as the bearings on our flywheel heat up. To solve this problem, we tried compensating for the increased flywheel speed over time by taking an average speed of the flywheel between shots and using it to adjust our voltage.. For teleop gear placement, we tried to use the ultrasonic sensor to limit the amount the robot can drive backwards when scoring gears to prevent it from driving too far back and bending the spring. However, we found that the ultrasonic sensor updates far too slowly for this to actually work right now, so we are investigating ways to speed up the ultrasonic sensor and use our drivebase encoders to compensate for this lag.

FRC Day 41 Build Blog

Day 41: Improving Gear Scoring

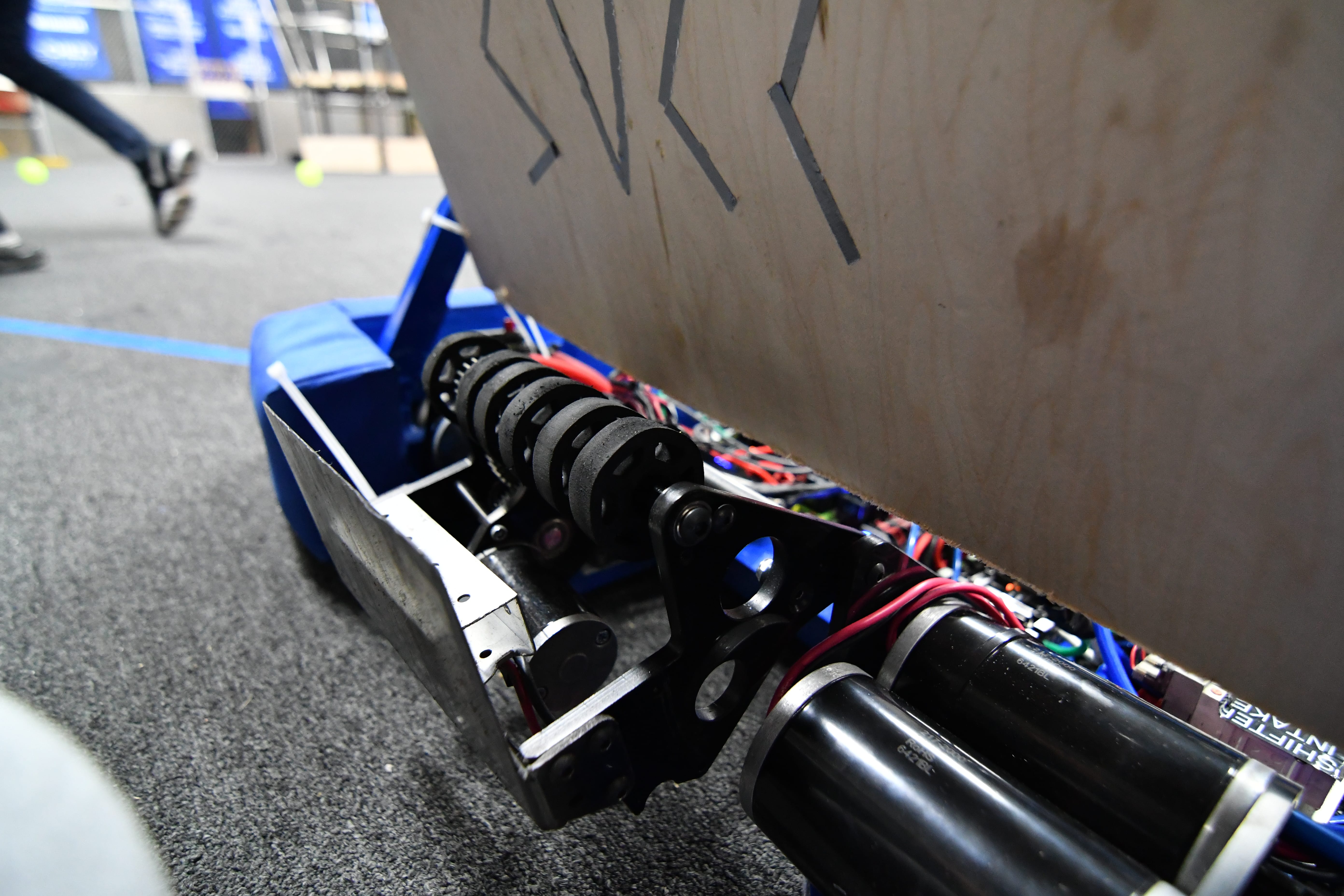

Gear Grabber

Today we worked on the Cow Catcher, or an assembly that prevents balls from getting stuck in the Gear Grabber and pushes balls out of the way. We began with prototyping with two delrin side plates and a 3/8" standoff, and while the results were promising, balls still got caught in the general vicinity, affecting its performance. To solve this issue, we prototyped the cow catcher with a longer standoff, which prevented balls from getting caught.

Having determined the relative effectiveness of the Gear Grabber, we began to design a deployment mechanism such that the cow catcher fits in the framer perimeter at the start of the match. We came up with the use of a torsion spring and hardstop to deploy the cow catcher at the start of the match. Due to the limited availability of springs at the lab, we used rubber bands instead, but the deployable cow catcher was ultimately too weak. Thus, we added standoffs and reinforcing plates to increase rigidity.

Robot Progress

We worked on fixing up our practice bot, making a new intake ramp and straightening out our hopper flanges. We also did a lot of shooter testing and were able to significantly improve the accuracy of our shots.

Silicon Valley Regional Tournament

This past weekend, we competed at the Silicon Valley Regional at San Jose State University.

Qualifications

Throughout the qualification matches, Misfire performed very well, despite bearing one loss, going 8-1 overall and scoring an average of about 300 points. We focused on a strategy of reaching 40kPa along with delivering a couple gears to maximize the amount of ranking points we would receive, which worked out as we were seeded first heading into eliminations

Eliminations & Awards

In our alliance, we picked Team 604 “Quixilver Robotics” and Team 4990 “Gryphon Robotics.” With this alliance, we aimed to focus both on fuel and gears, hoping to reach 40kPa+ in the boiler, 4 rotors spinning, and all robots hanging in an ideal game. During quarterfinals, we beat the prior record of 506 points with no penalties by scoring 507 points and later in semifinals we scored 509 points. During finals we finished off with scoring 522 points (517 without penalties)!

Through the eliminations, we ended up winning the tournament after an exciting final match! We won the Quality Award and were recognized for being captain of the winning alliance. It was a great experience playing against all these teams and we hope to see some of them again at World Championships in St. Louis.

FRC Day 40 Build Blog

Day 40: Improvements for SVR

Driving Improvements

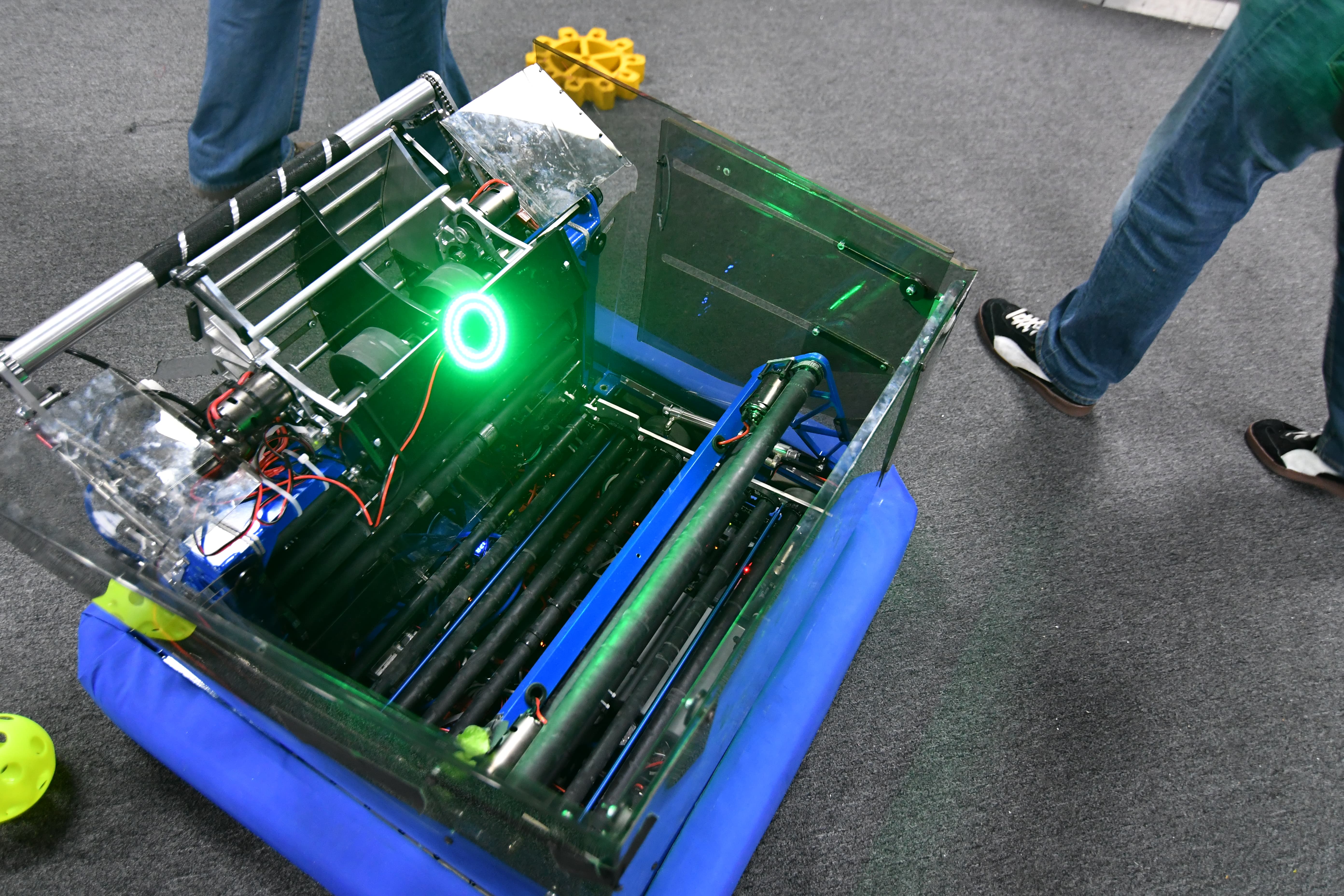

We added additions to our robot in order to create an easier and more efficient driving environment. We have placed a blue LED strip on the back of the hood to let drivers know whether or not they are in a good shooting proximity. To do so, we wired up MOSFETS to control the LED strip, which will plug into the DIO port on the roborio.

CamerasfAutono

At SFR, we found that installing “back-up cameras” would help with gear placement. Therefore, we worked on optimizing the camera placement, as well as finding a way to widen the narrow field of view (currently 70 degrees) to better capture the gear’s location.

Autonomous

After the post-mortem we worked to improve the robot's turning during autonomous. We prototyped small Delrin sliders that didn't quite work when sliding on carpet. We anticipate that the best solution will be to try to implement drop-down omni wheels that we can turn on. However, if that does not work either we will resort to changing the autonomous routine itself.

Misfire Reveal

Team 254 presents our 2017 entry into the FIRST Robotics Competition: Misfire. Misfire will be competing at the inaugural San Francisco Regional, followed by the Silicon Valley Regional and the St. Louis FIRST Championship. More information on the robot.

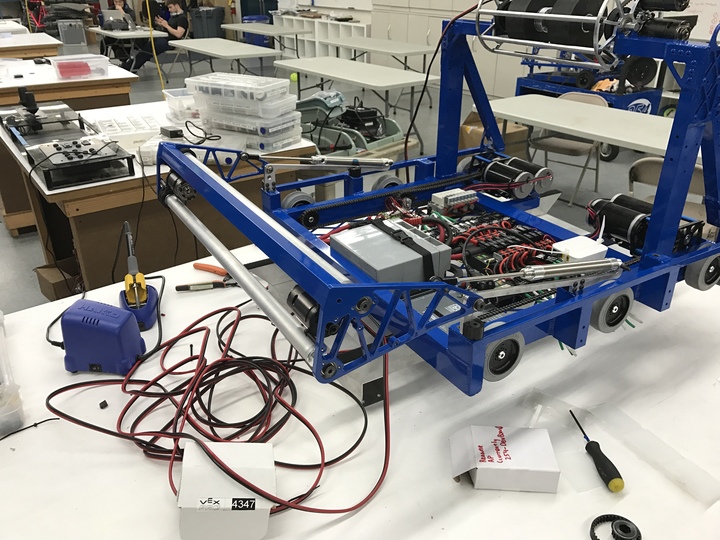

FRC Day 37-39 Build Blog: Preparing for Competition

Days 37, 38, & 39: Preparing For Competition

Intake

Today, we worked on fixing the intake after it broke earlier this week. After analyzing the strength of our current weldment and modifying it slightly, we decided that simply strengthening it would not help the fundamental problems existing in the design. We took one of the broken intakes and attached it to new polycarb side plates hoping that this would decrease impact forces by increasing the time of impact (change in momentum = force * time). We drove around and crashed the intake several times with minimal damage occurring, and we are proceeding with the new design.

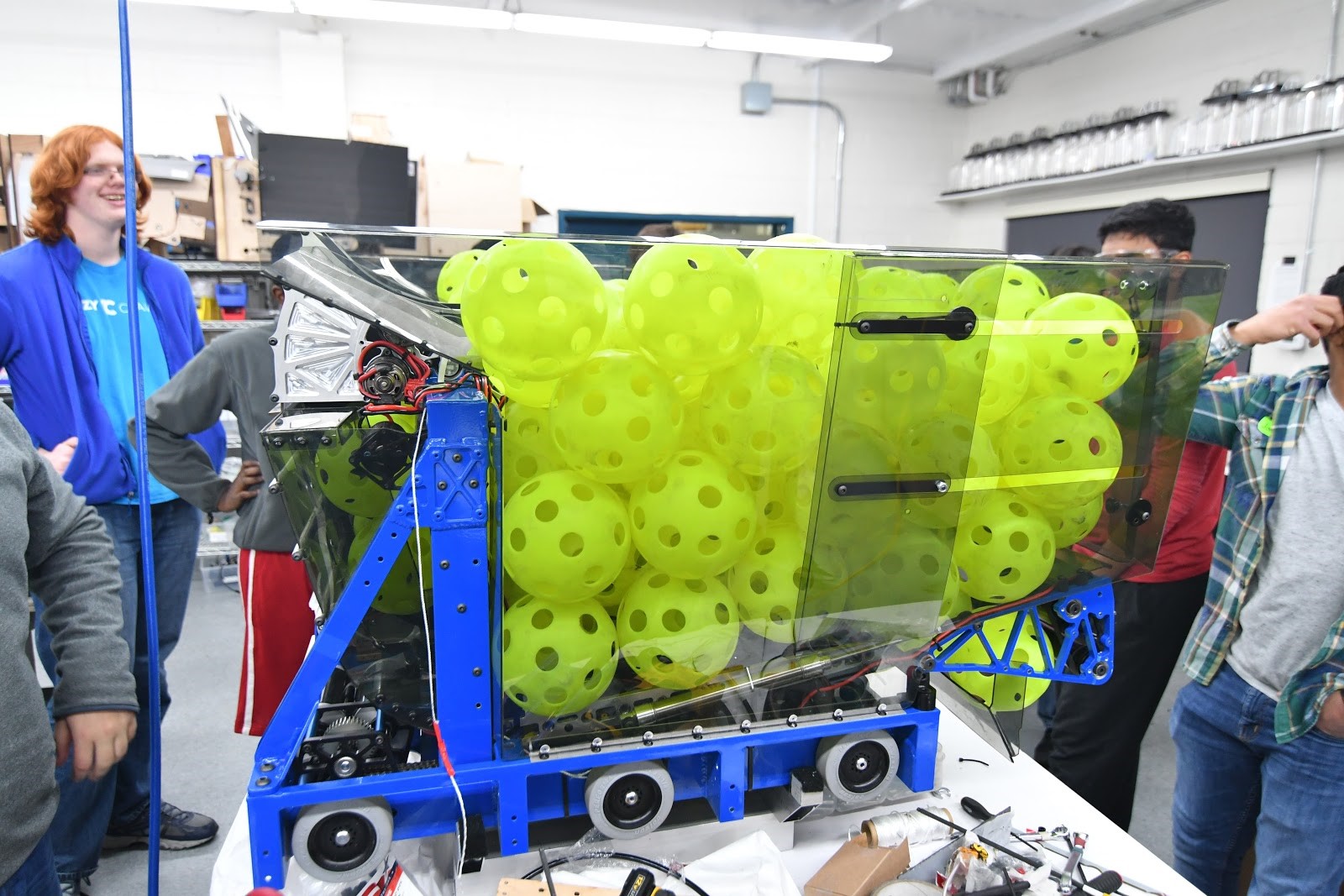

Hopper

Today, we worked on the Hopper and testing the fully assembled redesign. After fixing some initial discrepancies in the real life assembly, we tested out deployment and stowing. As of a few tests, the intake deployed well (after modifying the intake ramp slightly to have slightly deeper notches to fit the constraint screws in) and we will be updating the CAD with these changes on Friday. We will also laser cut a new intake ramp to get definitive results. If all systems work well after that, we will begin assembling the new parts for comp as well as a back up.

Between, Friday and Saturday, we were able to finalize the hopper design. After some CAD work on the redesign and some troubleshooting after assembly, we were able to make a solid hopper. More testing will continue to confirm consistency, but we will be moving forward with the Comp set soon.

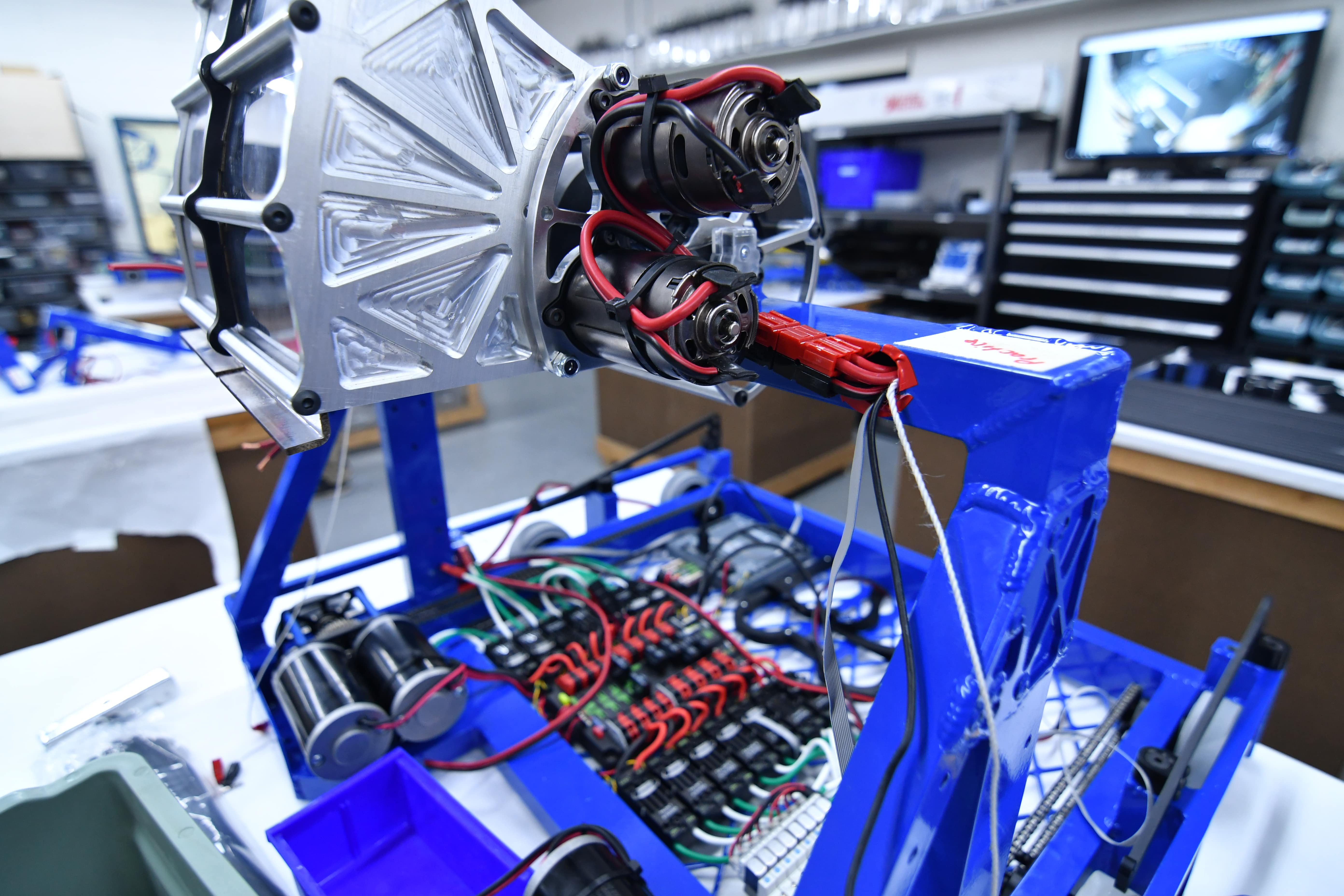

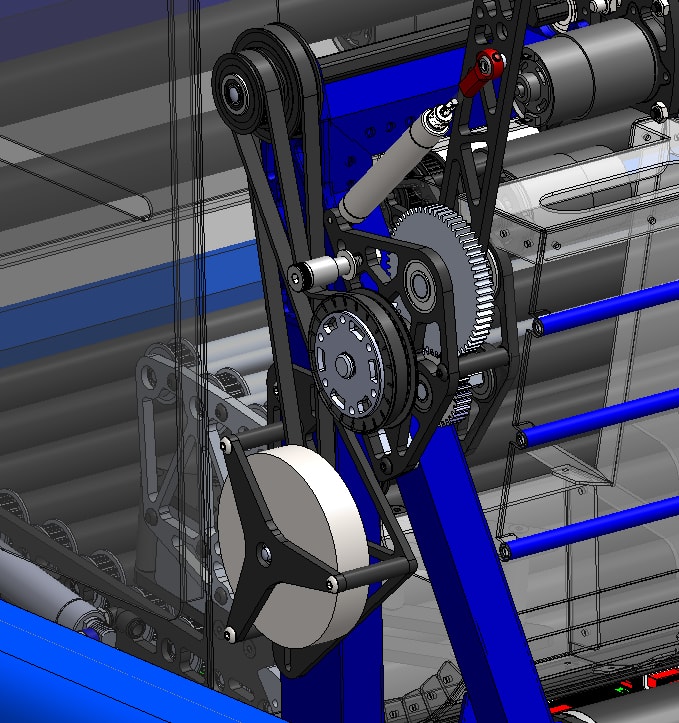

Shooter Flywheel

In the last week, we explored the use of a large flywheel to help increase the consistency of the shooter. A flywheel dramatically increases the kinetic energy of the shooter wheel system, hopefully reducing the amount that the wheel slows between shots. We designed a steel flywheel with about 4 lb*in2 of inertia. It is geared up 2.5:1 from the shooter wheel to increase the kinetic energy. Preliminary testing shows that adding the flywheel may not actually achieve the desired result. The elasticity of the timing belt caused some controllability challenges that the programming team worked on this weekend. Each time the direction of tension in the belt switched (from energy going into the flywheel to energy leaving the flywheel), there was a little bit of elastic movement which added oscillations to the shooter wheel system. The plots looked like the typical mass/spring/damper plots for a 2nd order system from a controls or dynamics class.

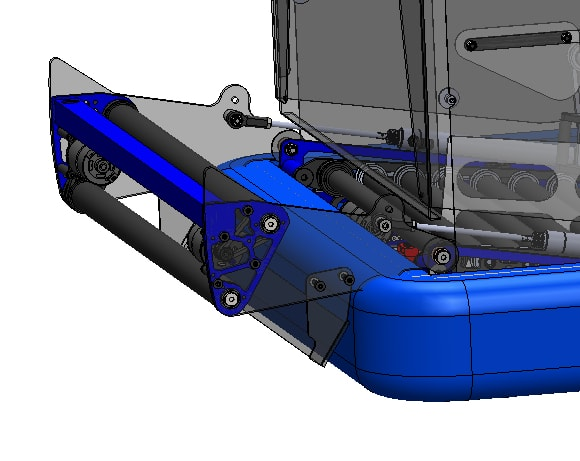

Climber

Climber

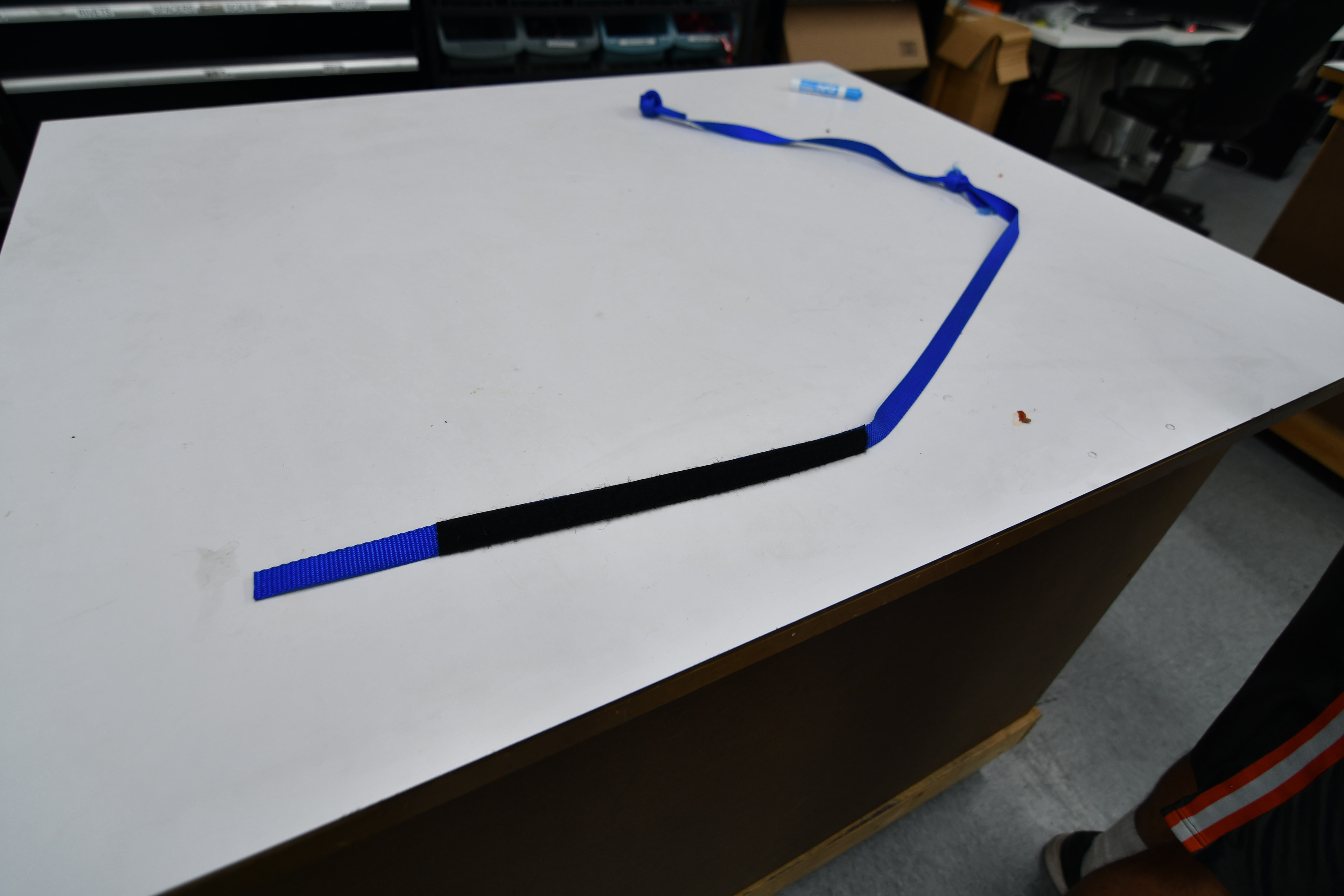

We are using inline elastic to add stretch to the rope. This will allow the robot to pull the rope down with a low amount of force at first, getting some wrap before beginning to lift the robot off the ground. This is important because the Velcro that engages the climber drum is strong in shear – and its strength is proportional to surface area. Once the rope has wrapped around the drum enough, the load transfer switches to Capstan forces. We are assembling several ropes, each with a number of pockets like the ones shown below.

A video is linked below of the climber being tested. Note that in this test case, we were pulsing the motors. Typically, the climb is much faster.

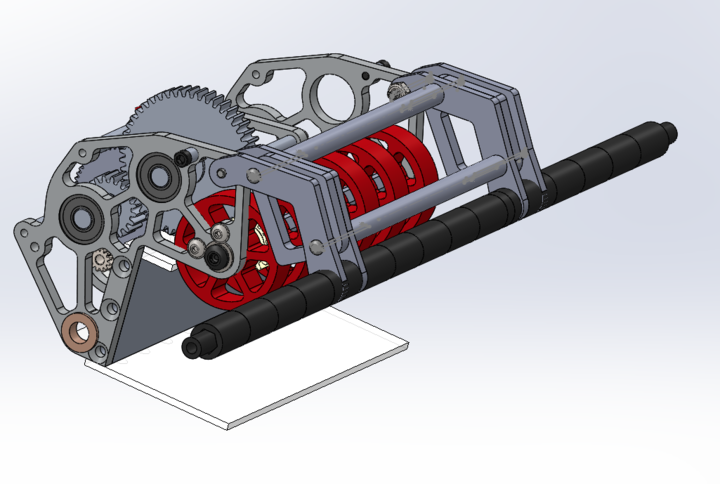

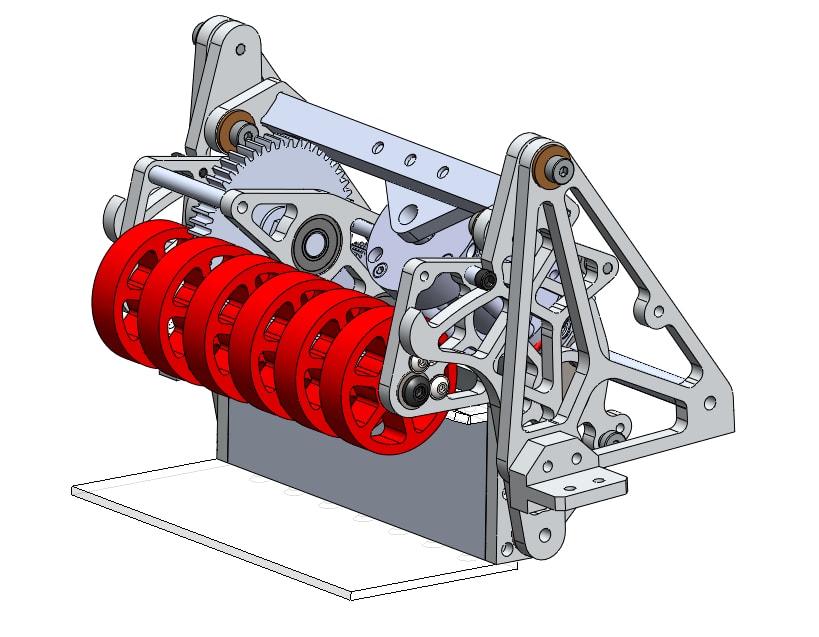

Gear Grabber

The latest iteration of the gear grabber has a dual pivot design – the whole mechanism pivots from a pickup configuration to a scoring configuration with one pivot, and a second lower pivot is sprung to allow the wedge to conform to the floor without digging in. We built this prototype last week out of delrin on the laser cutter and used it for driver practice over the weekend. We moved forward with making this out of metal and sent the parts to Anodize on Monday morning.

Check out the video below for pickup and scoring performance of the current prototype:

Driver Practice

We practiced driving by cycling gears with and without defense, climbing, and intaking balls off the floor. We are much better now at quickly scoring gears, and in one practice match we scored 9 gears and climbed when no defense was played on us. The gear grabber is much more reliable, and consistently picks up gears off the ground the second we touch them. Scoring is still tricky, but we are getting better at finding the right depth at which we need to drive into the spring.

Programming

Autonomous Program

Today, we worked on finding and fixing a bug in our Adaptive Pure Pursuit controller. The bug was causing arc lengths in the controller to be calculated incorrectly in some cases, resulting in a value much higher than it should have been. This would in turn cause the robot to drive way too fast and shoot past the end point in the path.

Gear Grabber State Machine

Today, we worked on implementing a new Gear Grabber state machine. The new gear grabber code greatly simplifies the operator controls. Now, there are only 2 buttons used for intake and release. The state machine uses output current to determine when a gear has been picked up and will activate the piston automatically.

More Information

We also found two bugs resulting in the robot not turning left and twisting along an autonomous routine, and we were able to fix these edge cases.

The hardware team began crimping and attaching 15 battery leads and running battery tests to determine true battery capacity.

FRC Day 36 Build Blog

Day 36: Improving Subsystems

Hopper Floor

Today we ordered all the the parts for the upper extension of the hopper floor and got majority of the CAD done. We will be going with 50 degree edges made out of Delrin with the first two rollers of the upper extension not having any surgical tubing to allow for horizontal movement.

Feeder

Today we worked on inventorying all the COTS parts for the Feeder subsystem. This would allow us to become more organized and make sure parts we need we have or are buying. I also helped lead students in inventorying other subsystems via the CAD,

Gear Grabber

We worked on the gear grabber. We removed the polyurethane added before with black, conforming WCP wheels. We found them to work significantly better than the polyurethane, but still not extremely well. We continued to work and changed the WCP wheels to red conforming wheels, which while ugly, worked better.

FRC Day 33, 34, & 35 Build Blog

Days 33, 34, & 35: Preparing for Competition

Gear Grabber/Driver Practice

We worked with the drivers over the weekend, doing basic drills like gear cycling, in order to become accustomed to driving the robot prior to the SFR Competition. We started the day by iterating on the floor for the gear grabber. The floor pickup for gears still needs work as it is inconsistent at picking up the gears when we drive into them. The polycarbonate knife edge was not as smooth as the prototype. There was a small edge on the actual version which was causing problems, so we sharpened it. After iterating on it, we then mounted it, and set ourselves on solving the jackknifing. We realized the best solution for this would be to redesign it, so Andrew and Mani are working on a new CAD. Meanwhile, the group worked on iterating on the length of the polycarb. We still have work to do before we finalize the design.

Bumpers

The major problem we were trying to solve was that the bumpers were too low. This was because the mounting solution uses C-channel brackets that go around the bumper supports and are supposed to sit flush to the underside of the little 1/2 x 1/2 bumper rail. But, what we didn’t realize is that the rail actually has a weld bead under it so the brackets could not go up high enough. This made the bumpers too low to the ground. To fix this, we removed a couple staples and pulled back just a bit of fabric on one of the practice bumpers so we could remove the brackets without actually remaking the entire bumper. We used the mill to make the brackets shorter, so they can move up and avoid the weld. We also used the drill press to add a new hole so they can align to the holes already drilled in the robot. This works pretty well, but some concerns are that the bumper is now too high and lifting the intake up, preventing it from going down far enough to have good compression on the balls. As of now, the intake is working fine. We still need to mill down all the other brackets, and we talked about making new ones and getting them anodized for the competition bumpers. The red comp bumper still needs fabric, and the blue one should have the fabric removed.

Hopper

Over this weekend, we worked on the hopper redesign. After some initial tests, we found that perhaps preventing the hopper from expanding sideways in the front expansion might add rigidity and strength to the hopper. To do this, we tested by bolting the front sliders to the hopper to prevent them from sliding. After testing, however, we found that intake by actuating the field hopper became difficult as the decreased width of the hopper prevented the balls from coming into the robot. To accommodate this, we redesigned the hopper in CAD so that the top will slide out vertically while the bottom pivots about a fixed point that torques the flexible polycarbonate. We also started the CAD of the new hopper floor for SFR which has the top rollers and wedges and a center to increase our ball throughput. We started the construction of the wedges on the hopper floor. After some brief testing, we CAD-ed this out. We will begin manufacturing on Monday.

Hanger Rope

This weekend, we received the 3/4” ratchet strap climbing ropes with the sewed on velcro. We tested it by pulling on it and rubbing it at corners in order to see distressing. The rope was then tested using the rope climber on the practice robot but the lack of stretch/slack made it hard to latch onto. In the near future, the rope team will attempt to plan out elastic placement on the rope.

LED Light

We wired up a MOSFET to control the switching of the LED light, located on the front of the robot, by having a voltage signal sent out from the relay port of the Roborio. It allows the drivers to see better when having to place a gear without the light blinding them.

Programming

Autonomous Program

Today, we worked on creating a reliable 40 kPA autonomous mode. We decided that previous autonomous modes that used complicated S curves to swerve into the hopper were too inconsistent, so we settled for a new, much simpler mode. But, at the end of the night, we had a working auto mode that deployed the intake, rammed into the hopper head on, waited a few seconds for balls to pour in, then aimed and fired the balls into the goal. We continued to improve the efficiency of this autonomous mode until we had it begin shooting around 6.3 seconds or less. We needed the autonomous mode to begin shooting as early as possible because there is around a 5 second delay between scoring a ball and having the scoring system pick it up. Because of this, any balls shot past 10 seconds will probably not be scored during auto.

We continued revising our robot's autonomous routines, and we were able to drive to the hopper and trigger it, receive a payload of balls, and fire into the boiler.

We also worked on a live data plotter that could plot robot data much faster than SmartDashboard. Various subsystems, such as the drivetrain, simply push data to a server, which pushes data to a grapher website on the driver station. This utility will be useful for tuning drivebase and shooter PID, as well as other programming tasks.

FRC Day 32 Build Blog

Day 32: Continued Assembly and Programming

Gear Grabber

Today, we worked on designing and testing the roller gear grabber. We installed a prototype onto the programming robot, and it worked somewhat well. When we drove into a gear directly, it was always ours, but it was narrow and difficult to always aim correctly at the gear. We played around with passive funneling, but were unable to significantly improve the width from which we can intake because of the sidewalls of the rollers were too low. Griffin and Colin are currently designing a new gear grabber that will likely funnel more effectively, and we plan to have it on the robot and testing it on Friday.

Hopper Floor

We took the top roller prototype that we have been working on, and added a center wall. The one from Monday was not long enough, so we extended it and stiffened it. We found this to help immensely. We also added zip ties across rollers to help the balls move across faster. We have reached a point where we are comfortable and confident with the floor.

CAD

We made progress on the hopper improvements in CAD and the redesigned Gear Grabber. We determined the geometry for the gear intake, designed the gearbox, and made the basic assembly that will be developed upon later.

Programming

Today, we worked on improving the web interface for the autonomous pathing tool. We improved the overall aesthetic of the app, and added several new features. These include the ability to see robot start and end rotation, and having the path colored based on the current speed of the robot.

FRC Day 31 Build Blog

Day 31: Continued Assembly and Programming

Hopper

On Monday, we worked on making the hopper more rigid as well as tackling other issues with it, including breach of size constraints and inability to actuate field hopper. We brainstormed and tested off of current practice-bot hopper with small team to determine solutions. We plan to change the front extension components to prevent them from expanding sideways by making it one piece. We will also lower the hopper to fold over the intake to give it greater strength and rigidity. As a result, the hopper will fold have slightly less volume for ball storage, but much greater strength.

Rope Climber

The rope design has been prototyped. The length and placement of velcro on the rope as well as the knot have been measured. The rope has not been tested or sewn on with velcro yet. Next build, we will attempt to prototype elastic and the placement of elastic on the rope as well as the amount.

Hopper Floor

We constructed a new top roller for the hopper floor. We also made few wedges at different angles to see which angle was best in directing each ball towards the shooter. Once we find the ideal wedge angle, we tested it. It worked well during the first test, but it was not consistent. Next time, we should keep experimenting in order to find the proper wedge angle.

Programming

We continued testing a ball counter for the shooter, but we were not able to count balls fast enough with the shooter on full power. For the counter, we’re using a Sharp distance sensor and creating a threshold that returns true when a ball is within range of the sensor. It is likely that our voltage threshold for the ball counter is too wide, causing some balls to not be detected.

FRC Day 29 & 30 Build Blog

Day 29 & 30: Getting Ready for Competition Season

Assembly

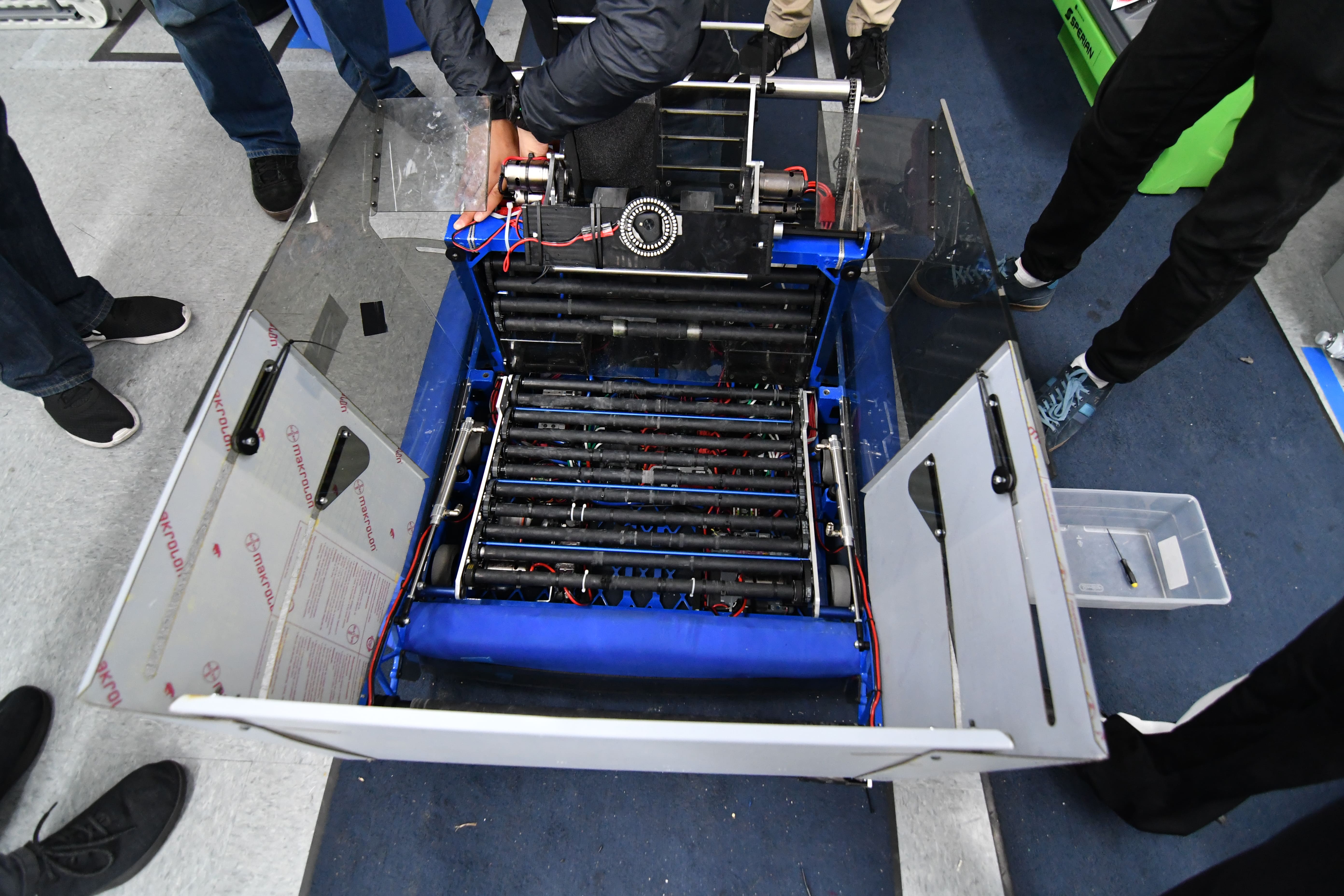

Hopper/Hopper Floor

Today, we worked on solving the funneling speed issue by placing a set of 4 rollers at the end of the hopper floor and above the wedges to provide a force pushing the ball forwards. This worked extremely well as our output increased to around 10 balls per second. More work needs to be done with different wheels and friction surfaces on the rollers and wedges to further increase our output.

Programming

We worked on pneumatically actuating the gear grabber by activating the solenoids individually. We are going to work on a state machine for Monday to make it more intuitive for drivers. We also deployed a sine scaling function to the driver inputs to significantly improve robot driving. We tuned the path following program by fixing some bugs and also investigated using the talon magic motion profile. We also developed the state machine for the gear grabber.

FRC Day 28 Build Blog

Day 28: Bag and Tag Day

Robot Progress

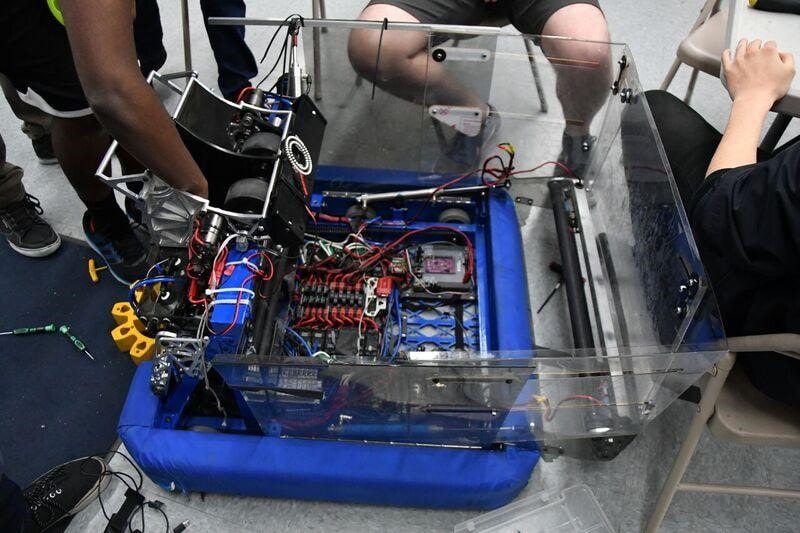

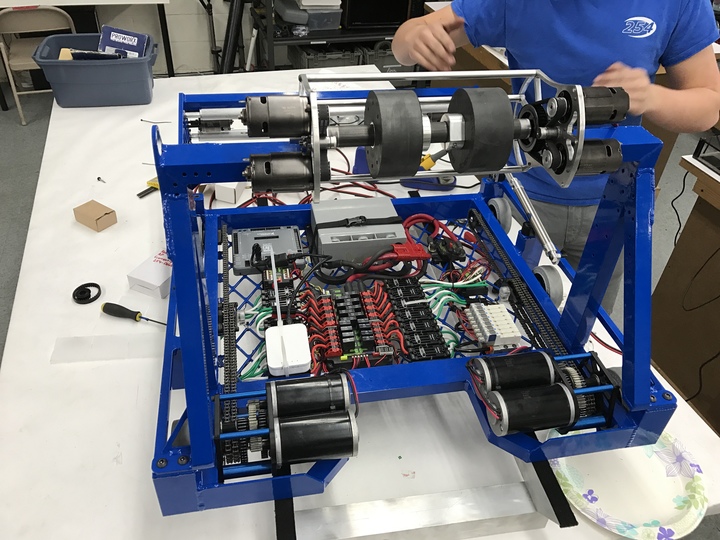

General Assembly

Today, we started by receiving news that after visiting 3 anodizing places, we could get parts for our hopper and hanger anodized for the competition robot. After calling, we knew that we would receive parts by 4, so we had to get everything ready for that time. The first thing we did was find every screw, every tool, every part, needed to assemble those subassemblies the moment they arrived. We then, finished the side panels and assembled the hopper. As soon as the parts arrived, we built up the entire robot and cleaned it, the best we could. We proceeded to take robot photos, and then diagnose the robot.

We also spent majority of the day working on a battery tab mount to keep the battery leads away from the hopper floor. The battery tab mounts to the PDP and fastens the Andersons together.

We found the shooter to have some issues that need to be dealt with, but physically fixing them must be pushed off until SFR. The robot was bagged around 10 minutes before 9pm.

Hopper Assembly

Yesterday, we worked on assembling and attaching the hopper container. While we waited for the anodized parts for the hopper floor and climber to come in, a group of students worked on assembling the main components of the hopper while carefully avoiding smudging the sponsor side panels before pictures. After prepping everything and waiting for other subsystems to be assembled and attached, we riveted and bolted on the hopper in under 10 minutes to allow media time to take pictures and then carry out any final checks before bag and tag.

Programming

Today, we worked on tuning our autonomous program some more. We discovered that the bug from yesterday was caused by two segments of the path not lining up, causing the pure pursuit controller to go out of control as it attempted to move the robot to the correct position. We managed to get a fully working autonomous mode that scored a gear, activated the hopper, then shot around 40 balls into the boiler. We noticed some inconsistencies with the gear scoring segment of the auto, most likely caused by wheel slippage. We didn't have enough time to fully resolve this issue, so we will continue to work on it this weekend.

FRC Day 26 & 27 Build Blog

Day 26 and 27: Continued Assembly and Programming

Assembly

Hopper

Today, we made sizable progress on the hopper. We made an initial prototype which we iterated upon to account for unforeseen difficulties. After getting it to deploy efficiently, we were able to store a max ball capacity of 140 balls. We are struggling with rigidity, however, as the 1/16 polycarbonate hopper flexes greatly when under stress from the balls and simultaneously driving. We will put aside fixing this problem for now as we have to finish putting together a robot for bag and tag.

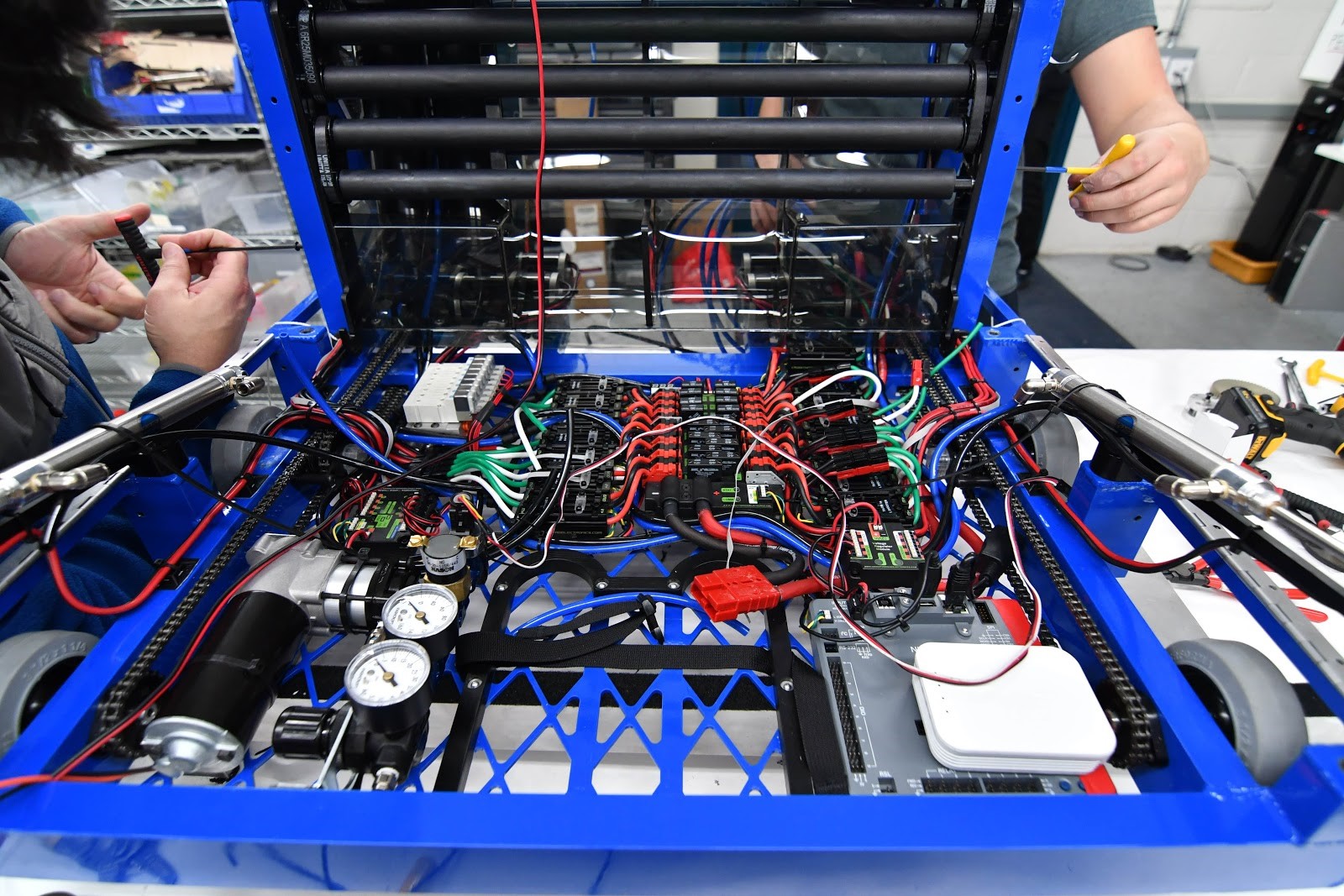

Wiring

We have almost completed wiring on the practice robot. We are waiting on a few competition subsystems to be assembled then we will be moving on to pneumatics. Last night, we had the robot shooting a few balls. Once we finish the hopper, we should be able to practice driving.

Gate Latch

On Sunday build, we worked on a hopper gate latch to lock down the assembly during the match. Changes still have to be made to make the latch feasible.

Hopper Floor

Today, we worked on assembling the hopper floor and finalizing it. We completely finished construction of the hopper floor. We worked on pneumatics and fixing the pneumatic tubing on the competition robot. We made progress on the side panels, which are coming along nicely. We also worked on general parts of the robot, but we still have a lot to do before tomorrow.

Programming

Today, we worked on creating an updated version of the Waypoint maker app. This new app outputs java files to load on the robot. We also created a parser on the robot which converts these waypoints into path segments for the Adaptive Pure Pursuit Controller.

Another project we worked on was implementing a turn in place autonomous action. We also made a couple auto paths to drop gears off and activate the hopper. We ran into some problems with motion profiling that we will fix tomorrow.

We rewrote the TCP server which sends data about the robot state to a web interface to be graphed. We used a library found on GitHub to do this. Next time, we will incorporate this into the rest of the Robot code and test it with the roboRIO.

FRC Day 24 & 25 Build Blog

Day 24 and 25: Continued Assembly and Programming

Assembly

General Assembly

We have almost completed wiring on the practice robot. We are waiting on a few competition subsystems to be assembled then we will be moving on to pneumatics. Last night, we had the robot shooting a few balls. Once we finish the hopper, we should be able to practice driving. The programming team finished vision tracking to auto-aim at the vision target on the goal.

Hopper Floor

We assembled the hopper floor. The hopper floor originally had a .0010 nominal distance for the pulleys. After making the plates, we found that such a small distance caused too much tension, so we had to redesign it. We then, laser cut 5 different plates ranging from .0020 – .0060 of an inch.The .0060 of an inch measurement was the best way to go. Then, we put this measurement into the CAD and remachined those plates, which were put together. But, it was still too tight and required spacers in the standoffs. We put the spacers and it improved feeder consistency and reduced feeder tension. For the feeder, we had no way to service the 775’s due to very quick design restrictions, which would not be good at competition. So, we created holes on the side and top polycarb plates on the chute itself.

Hopper Feeder

Today, we worked to lock down the design of the climber for the robot. We will be using a winch which it connected to a power take-off from the shooter to use the 4x 775 pro motors there to climb. The winch starts stowed against the hood and is deployed by pneumatic cylinders to the perimeter of the robot size box after the start of the match. Note that there will be hard stops (rope or cable) so that the force of hanging does not pass through the pneumatic cylinders.

The winch is connected to the shooter shaft with a hex coupler and a pulley which rides on a one-way bearing on a shoulder bolt. When the shooter spins in forward, the bearing will clutch. When the shooter reverses direction, the bearing will lock and drive the winch. Note that the shoulder bolt is left-hand threaded so that the torque of climbing tightens the bolt.

The total gear ratio is 25.7:1 from the 775pro motors. This should give an expected current draw of around 80 amps when climbing. The 12:36 reduction is in the shooter gearbox. The 18:36 reduction is the belt between the shooter and the climber gearbox. The 14:60 reduction lives in the climber gearbox (with a 30T direction-reversing idler gear) and the 1:1 reduction is the chain from the gear box to the winch spool.

We plan to spool up a piece of velcro-coated webbing on a 1.25" diameter 1/8" wall thickness aluminum tube. FEA simulation shows that the expected bending on a 23" long tube of these dimensions should be around 1/16" in the middle (with purely elastic deformation).

Work still needs to be done on detailing the right side support plates, and the drum.

Bumper Construction

Today, we worked on building the bumpers for the robots. We made 4 bumper frames, secured pool noodles to the outside of all 4, and put sailcloth around 1. We will finish up the sailcloth tomorrow, and we plan to put on the team numbers soon as well.

Gear Mechanism

We assembled and began to test the existing gear mechanism with the "fingers", but it had a few flaws. One group worked on fixing the existing gear grabber, while another prototyped another design using compliant wheels and a polycarbonate wedge on the bottom. The initial prototype was promising, but needed some work in order to be consistent. We plan to continue working on both tomorrow.

Programming

Autonomous Path Follower

We began integration of the autonomous path follower into the main framework of our code and began debugging the path follower. We discovered some issues but were able to solve most of them.

PixyCam System

Today’s biggest accomplishment was finalizing all the state machines for the Superstructure. Because of this, we were able to automatically detected the boiler goal, align to the boiler, and shooter balls towards it. This is a major step forward since we were able to integrate across multiple subsystems.

FRC Day 23 Build Blog

Day 23: Continued Assembly Hopper Progress

Robot Progress

Almost all our parts are back from anodizing and we are trying to rapidly assemble as much of the robot as possible. The team working on putting surgical tubing over the rollers is almost finished and just needs to trim the excess off of each edge. The intake team finished assembling their first subsystem and is ready to mount it to the robot and assemble the rest. They had some trouble locating the appropriate timing belts, but now are ready to assemble. The shooter team also collected all their hardware. They just need to laser cut the rest of the polycarb and delrin plates, assemble the other shooters, and mount on the robot. Superstructure wiring was set back when we had to unfish the wires and drill additional holes in the weldment, and we are not back on track and ready to terminate the shooter wires. Late in the evening, a team of students and mentors stayed late to double check our inventory to ensure that we have ordered everything that we need to complete the robot by Tuesday. We are hoping to finish assembling intakes, shooters, and feeders today and at least one conveyor assembly as well. Wiring should be able to finish the practice and comp robot shooters and begin wiring the other subsystems.

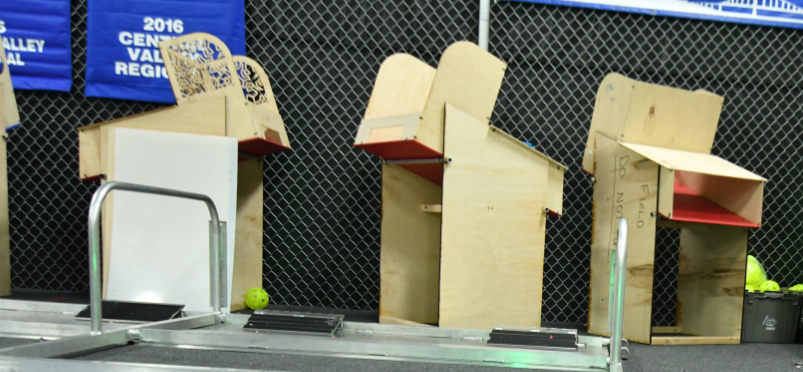

Field Construction

Today we have finished all the feeders for the field by attaching the tops to the base. We have all the polycarb cut for the hoppers, but need people to cut the pipe that slides in and zip tie them on. The prototyping for the driver station to boiler mount is almost finished. The final idea has been decided and is going through final stages of being designed. The 2×2 wood for the boilers net have been cut, and all that is left is to place them on and attach the netting.

Programming

We decided to scrap the PixyCam system and use two separate camera systems, the Android phone, and a webcam connected to the RoboRIO. The Android phone system is the same system that we used last year but trained for this year’s boiler targets. We worked on getting the phone mount ready to mount on the robot. The webcam will be used for the gear placement; it connects to the RoboRIO via USB and serves live video to SmartDashboard via MJPEG. We were able to view a live stream of video on SmartDashboard, and we began work on identifying the boiler targets with the webcam’s stream on the RoboRIO.

We also worked some more on the Autonomous Pathing system. First, we got the pathing system working with the new RobotState class, replacing the old Odometer class to keep track of robot position and heading. We also added linear interpolation to the lookahead point of the last segment of the path. This was in order to fix a problem where the robot would jerk sharply at the end of the path, causing its heading to end up out of place. Finally, we worked on tuning the wheel radius so the RobotState class would give a more accurate position. After making these improvements to the pathing system, we worked on tuning PID for the drivebase using the built-in talon PID control. Tuning Kf went smoothly, but we ran into some problems with tuning Kp. Even extremely small Kp values would cause the robot to turn wildly, and we weren't able to find out exactly what was causing this problem today.

FRC Day 22 Build Blog

Day 22: Finishing Up The Field

Robot Progress

Today was a productive manufacturing and assembly day even though we didn't have our anodized parts back. We took off the superstructure today to make holes to run wiring from the shooter and feeder motors and encoders from the top of the superstructure to the drivebase. We began fishing wires, but were not able to finish because we have to add more holes to the superstructure to mount the feeder roller plates. Tomorrow we should have several parts back from anodizing and we can begin to assemble several subsystems including the intake, superstructure, shooter, and feeder. Manufacturing will also continue on the hopper polycarb pieces.

Field Construction

Today we finished up all 6 of the feeder stations for the field. We also changed all the plastic from the previously used HDPE to the new official colored plastic, which allows gears and balls to slide down it much more easily. We plan to continue with field work, with the next tasks being to finish the more complex airships and assemble the field side walls/driver stations.

Programming

We made leaps and bounds towards cleaning up our Github codebase and making work far easier Previously, our codebase had sprawled across multiple branches, each with their own versions of essential robot code, which made collaboration difficult. We merged the latest autonomous and camera code into the master branch. In the future, we will ensure that all code remains within three commits of the Master branch, and we will pull far more frequently.

We also began integrating the code for the Nexus phone camera system, as well as the robot state machine, into our codebase. The Nexus vision system was used with great success last year but is far more complicated than our PixyCam system. We will test the PixyCam again, using the central point on the top segment instead of the centroid (a far more consistent, reliable means of estimating the distance), and the accuracy/reliability will determine whether we use the PixyCam or the Nexus phone.

The drivebase PID control was tuned for our unweighted robot drivebase to compensate for mechanical differences. Previously, we set a constant voltage to the motor to control the robot’s speed, called open-loop control. This does not take into account different mechanical differences, like gearbox lubrication or bits of carpet stuck in gearboxes (a problem we saw). Now, instead of swerving, the drivebase drives in a straight line!

Finally, we began work on integrating an infrared laser distance sensor into our robot code. The sensor turns on a high-power infrared laser beam and measures the time taken for the beam to reflect back to a detector, then uses that information to calculate the distance between the sensor and the object. This “time of flight” sensor has great accuracy, and we envision using it in conjunction with our camera system to accurately measure distances and aim appropriately.