Day #12: More Machining!

Prototypes

Shooter

Today we made a few more changes to the shooter. We decided to return back to the larger, treaded wheels. Students disassembled the shooter and retreaded the wheels. Students also added snapring grooves onto the shafts. The shooter just needs to be reassembled and tested.

Programming

The programming team worked on a program to read constants from a text file into the robot software. This has been written and mostly finished, but remains untested. Since the cRIO runs only Java ME, an outdated version of Java compared to SE, the programmers spent a lot of time rewriting and reimplementing functions like String's split method. Meanwhile, other students continued debugging the Smart Dashboard widget and FTP connection, but had problems using the program on the driver station and other laptops. Oddly, the FTP upload and download works on one of the student's laptops, but not any of the others. More tests will be conducted to get to the root of this issue.

Programmers also began testing sensors for use on the 2013 robot. The gyro was removed from Skyfire and added to the 2010 robot for temporary testing purposes. Tomorrow, the team plans to test the S5 encoders and other sensors by printing out the values of the sensors to a console. This will also serve as a quick lesson on programming sensors for new and old programmers alike.

Programmers debugging issues with Smart Dashboard extension

CAD

Not much CAD work was done today as we focused mainly on machining the drivebase.

Manufacturing

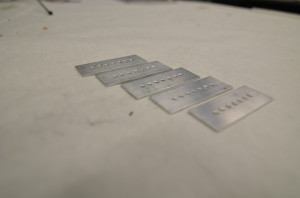

Today students did a lot of machining. They used the mill and drill press to create the Bumper Support Caps, which will get welded onto the drivebase. Students also used the lathe to cut down standoffs for the gearbox and to add snapring grooves the prototype shooter's shafts. A group of students also finished scotch-briting the bearing-housings. The CNC was used to make the final cuts onto the Bumper Supports.

Some of the many manufactured parts

Scotch-brited bearing housings

Student creating parts on the mill

Manufacturing parts on the lathe

Action Items

-

Test sensors (encoders, gyros, etc)

-

Test reading constants from file

-

Continue Manufacturing Parts, especially parts for drivebase.

-

Finish bumper CAD (start manufacturing bumpers after mentor approval)

-

Continue control board design (document functions, buttons, & layout)

Lab closing time for the night was 11:30 PM