FRC Season Day #1

Today was an extremely productive day at the lab. We built a significant part of the field, tested the game elements, began design, started manufacturing and continued to work on programming.

Field Construction

As soon as we got to the lab, a large group of team members got started building a replica of the most essential field elements – a rack and a tower. We intend to build enough of a low-cost field for testing and the NASA Robotics Alliance Project will purchase a complete field for the west coast in the coming weeks. The field will stay at our lab during the build season but will travel around the state for various off-season competitions afterwards.

Game Element Testing

After we had a basic understanding of what the rack was going to look like, we moved forward with game piece testing. We experimented with how far the tubes could be thrown and discovered that a well-trained human player could likely throw tubes across the entire field.

Programming

The programming team was working hard all day. They began the day by installing the new versioins of the programming software and then spent the day getting Onslaught to drive under driver control. The simulator group was working on data logging, 3d modeling and collision detection.

Design

After dinner, a group of team members met to discuss robot design. We immediately decided on a wheeled robot and decided that at least 6 wheels would be best for maneuverability. To save weight, we all agreed that it was not practical to consider building a robot with more than 8 wheels. We also decided that we would like a two-speed drivetrain with a high gear to quickly traverse the field and a low gear to push other robots out of the way if necessary.

When looking at the game field, we were very worried by a 1/4″ tall plate under the carpet surrounding each tower. The concept of a 6 wheel drive or 8 wheel drive drivertrain with dropped center wheels relies on the fact that not all of the wheels will be on the ground at all times to improve turning. We were worried that when in proximity to the plate under the field, more wheels would be in contact with the carpet which could inhibit turning. We thought that this might be a greater issue with the six wheel drive robots than with eight wheel drive robots, but decided to test to make sure.

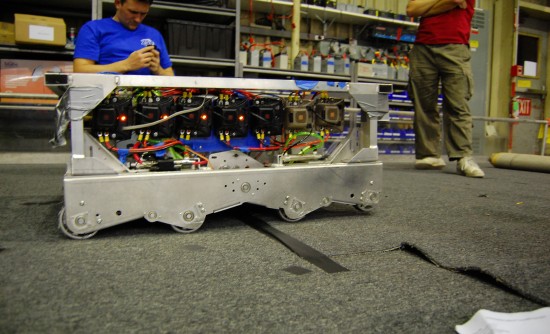

We put down a metal plate under carpet and tested it with both 8 wheel drive and 6 wheel drive robots. It was determined that the 8 wheel drive robots drove considerably better when in proximity with the plate when in high gear. However, in low gear, both robots had great performance as if the small bump wasn’t even there.

We took the data from our tests and moved on to discuss how important turning near the towers would be in high gear. It was determined that the only time turning near towers would be very necessary is when lining up to deploy the Minibot. We decided that this is only for about 5 seconds of the match and that there is no reason to not just use low gear during this time.

After we decided that it was not important to be able to turn in high gear near the towers, we all decided to move forward with a six-wheel drive robot. Everyone in attendance voted that the benefits of saving up to 3 pounds outweighed the drawbacks of potential limited turning in high gear when in close proximity to the towers and agreed that a six-wheel robot would be best.

The next topic that was discussed was traction. Although with ideal physics, contact area with the ground does not affect traction, it was determined through observation that due to the tread material interlocking with the carpet fibers, more contact area does indeed result in greater traction. Because of this, we discussed moving to slightly wider wheels in order to increase the contact area with the ground. We were worried that wider wheels could negatively affect turning so we decided that the robot should be designed with thin wheels (similar to what we have used before) but should be compatible with wider wheels if necessary.

Finally, we discussed speed. The consensus was that we want to be able to drive fast. However, no decision was made on exact robot gear ratios or speed. Both will be discussed and finalized tomorrow.

Manufacturing

As soon as it was finalized that we would be building a wheeled robot, manufacturing began on the bearing blocks to support the wheels. All of the stock for the bearing blocks was cut and the first operation began on the outside bearing blocks. We expect to complete the first operations on all of the bearing blocks tomorrow.