Day 9: Rollers Prototyped, Wheels Complete & Preliminary Electronics Layout

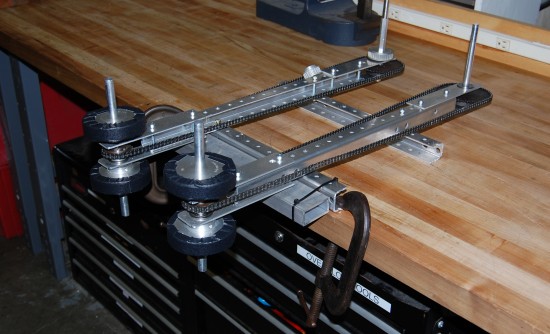

Rollers Prototyped

Today, our prototyping group finished putting together a jig for testing tube intake rollers. The prototype was very successful and successfully picks up and holds tubes. Furthermore, we were able to rotate tubes within its grasp by rotating the two rollers at different rates.

The design still needs to be tweaked for optimum tube grabbing performance.

The initial roller prototype. Driven by drills, the prototype is very effective at sucking tubes in and holds them quite well once they are in its grasp.

Manufacturing

After several days of hard work, the drivetrain wheels are finally complete. During machining, there was an issue with the original CNC code where the spokes were not being milled deep enough. This was resolved and the problem wheels were fixed.

The wheels look great and are visibly much smaller than previous wheels, as shown in the image below. The wheels will be anodized by sponsor Pacific Coast Metal.

The Evolution of Cheesy Poof Wheels. From left to right: 2006 6" Wheels, 2008 4" Wheels, 2010 4.5" Wheels, 2011 3.5" Wheels.

The DXF CAD drawing for the gearbox sideplates was created and sent to Mike D of Team 233 for Manufacture.

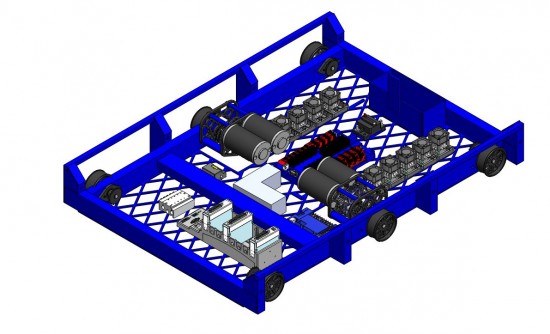

Design

Today, the design team worked on the electronics layout, the spool gearbox and preliminary design for the minibot. The electronics board is coming along great. We are happy with the positioning of most of the elecronics but are still not clear on where we want our compressor.

A second team worked on CADing the spool gearbox. An issue arose where one of the needed gears was not available, so we had to modify the gear ratios slightly. The design for the gearbox is coming along and should be finished tomorrow.

A third team started to analyze the parts available for the minibot and started to develop preliminary ideas for how to efficiently lift the small robot to the top of the pole. Work will continue into the next week.